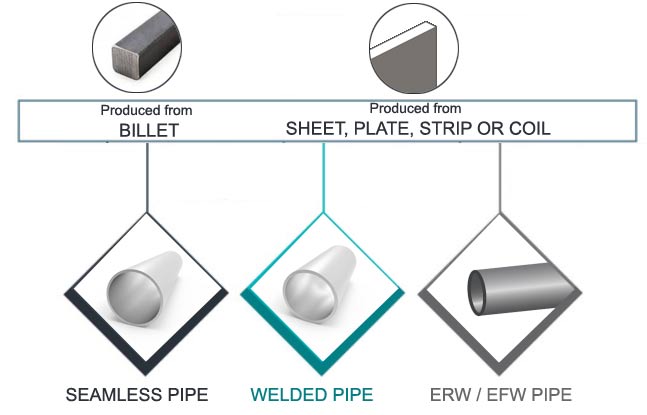

a seamless pipe is manufactured using extrusion process. the joint efficiency factor 'e' is 1. this method is recommended for category 'm' fluids.

erw pipes are manufactured when the sheet metal is overlapped and a bias is applied to develop resistance between the sheets. the heat developed causes the sheets to fuse together. the joint efficiency factor 'e' is 0.85. used for category d fluids.

note :

category d fluid service is the less hazardous service. it includes fluids that are nontoxic, nonflammable, and not dangerous to human tissue and are at a pressure less than 1035 kpa (150 psi) and temperature from -29°c through 186°c (-20°f through 366°f).

category m fluid service is a fluid service in which both of the following two conditions apply:

a) the fluid is so highly toxic (poisonous or lethal) that a single exposure to a very small quantity of the fluid, caused by leakage, can produce serious irreversible harm to persons on breathing or bodily contact, even when prompt restorative measures are taken.

b) after consideration of piping design, experience, service conditions, and location, the owner determines that the requirements for normal fluid service do not sufficiently provide the leak tightness required to protect personnel from exposure.