what is drill pipe?

drill pipe is hollow, thick-walled piping that transmits drilling fluid and torque through the wellbore to the drill bit on a drilling rig.

the drill pipe can be classified according to many parameters such as length, diameter, weight, upset and grade of steel. there are many factors which can influence drill pipe selection:

- hole size

- circulating and drilling parameters

- casing and cementing requirements

- hoisting capacity

- pipe availability

length

the drill pipe can be available in three length ranges:

range 1 (r1) is shortest in length, more common for sizing production tubing or casing, and ranges from 18 to 22 ft.

range 2 (r2) is considered the standard length for drill pipe and ranges from 27 to 31 ft.

range 3 (r3) is common in casing and also deployed in deep water drilling applications. the increased length decreases the number of tool joints in each stand of drill pipe. the fall back being that the load exerted on each tool joint is greater increasing wear and reducing the expected life of the drill pipe. r3 ranges from 38 to 45 ft.

range 2 is the most commonly used.

drill pipe strength

the strength of the drill pipe can be defined according to:

- pipe body yield strength: it can be presented by the resistance of the pipe body to the axial tension

- collapse resistance: it is presented by the ability of the drill pipe to resist to the external pressure

- internal yield pressure: it represents the ability of the pipe to withstand the internal pressure

- torsional yield: it is the resistance to the torque

grade e drill pipe, referred to as "mild" steel, exhibits the lowest yield strength per unit area with a yield strength of less than 80,000 psi. it is able to withstand a greater percentage of stretch or "strain" prior to fracture than higher strength drill pipe grades. it is also more resistant to corrosion and cracking. grade e is utilized in medium depth wells from 10,000 to 15,000 feet.

grades x-95, g-105, and s-135 are considered high strength grades. they exhibit increased yield strength which is required to service deeper wells.

api drill pipe grade | minimum yield strength (psi) | minimum tensile strength (psi) |

e-75 | 75,000 | 100,000 |

x-95 | 95,000 | 105,000 |

g-105 | 105,000 | 115,000 |

s-135 | 135,000 | 145,000 |

upset

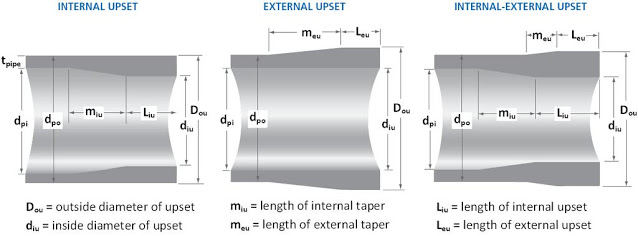

the upset (thread-end finish) refers to the wall of the tool joint at the threaded connection. drill pipe is offered with an internal upset (iu), an external upset (eu), or an internal-external upset (ieu).

ieu (internal-external upset) – the tool joint od is larger than the od of the drill pipe and the tool joint id is less than the id of the drillpipe. generally, ieu tool joints are the strongest available. so, the large od and small id of the tool joint cause relatively high external and internal pressure losses.

eu (external upset) – the tool joint id is the same as the id of the drill pipe to minimize internal pressure losses. the upset is on the od of the tool joint.

iu (internal upset) – the tool joint id is less than that of the drill pipe. so, the small id causes relatively higher internal pressure losses. the tool joint od is the same as the od of the drill pipe. this type is called slim-hole drill pipe because of the small od.

tool joint

each end of the pipe incorporates a tool joint, and is differentiated by the male threaded connection referred to as the "pin" and the female threaded connection which is referred to as the "box". they are pre-fabricated and welded onto the pipe. the tool joints provide high-strength, threaded connections. they are heat treated to a higher strength than the steel of the tube body in order to survive the rigors of drilling and numerous cycles of tightening and loosening of threads. tool joints are specified by upset and thread type.

threaded connection

tool joints incorporate threaded connections. they include standard api threads as well as proprietary threads. each type of threaded connection is specified by threads per inch (tpi) and it's taper. common api tool joints include regular (reg), full-hole (fh), and internal-flush (if).

get a competitive drill pipe quote

if you’d prefer to discuss your drill pipes requirement please email us at – sales@bestarpipe.com for competitive quote on any quantity or specification required.