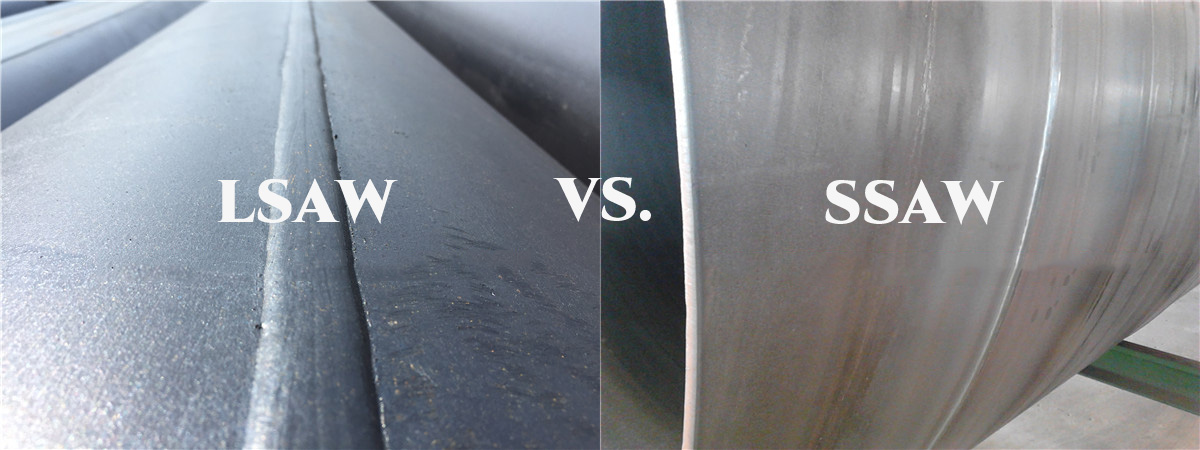

lsaw and ssaw are variants of saw (submerged arc welded) pipes. the difference between them is the way they are welded. in lsaw pipes, the welding is longitudinal, which means that steel (hot rolled coil plate) is rolled into a pipe and the seam is welded longitudinally. in the ssaw type, steel coils are welded spirally, like a helix, so that the coil (strip) assumes the shape of a pipe. saw pipes are used mainly in oil and gas transportation. on the other hand, seamless (non-welded) pipes are mainly application in oil and gas exploration projects.

difference in length range :

length of lsaw steel pipes range from 3 m to 15 m. the maximum length of the lsaw steel pipe is 15 m. if you want longer it should choose the t-welded pipe.

ssaw steel pipe can be produced in longer length (maximum length up to 50 meters) compared to lsaw steel pipes.

size range and performances:

outside diameter of lsaw pipe ranging normally from 16 inches (406.4 mm) to 60 inches (1524.0 mm). wall thickness from 6.0 mm to 30.0 mm. good performances on high-pressure resistance, and low-temperature corrosion resistance.

while ssaw steel pipe diameter range is from 8 inches (219.1 mm) to 120 inches (3040.0 mm); wall thickness from 5.0 mm to 25.0 mm.

the advantage part is we can get the different diameter of ssaw pipes with the same size as the steel strip, there is a wide application for the raw material steel strip.

application difference:

application of lsaw steel pipes have been widely used in the oil and gas pipelines, especially required large diameter and thick wall pipe with high strength and long-distance. meanwhile in construction of a structure that needs tough strength, water treatment, thermal industry, bridge building, etc.

according to api specifications, the lsaw pipe is specially designated in large-scaled oil and gas transportation, in the cases that pipeline across the city, sea, and the urban area.

as we know, ssaw pipes used for oil and gas pipeline systems. but in petroleum design specification, the ssaw could only be applied in construction structure, water transport and sewage treatment, thermal industry, building, etc.

price:

for different use of the raw material, the price of lsaw is higher than the ssaw steel pipe. but the lsaw has better performance than the ssaw steel pipe. for commonly used steel grade, the moq for the lsaw pipe has no limitation while ssaw is about 20 tons per size.

overall, lsaw pipes has better performance than ssaw pipes. below points explains it why.

ssaw pipes has greater residual stress than lsaw pipes. lsaw pipes passes through uniform expansion process.

ssaw pipes weld stress concentration phenomenon is serious. the heat affected zone of ssaw pipes is larger than lsaw pipes. heat affected zones are considered weak points where failure might start.

geometry accuracy of lsaw pipes is better than ssaw pipes, a key in the ease of installation.

the welding line of lsaw pipe is around 60% lesser than of ssaw pipes.

using steel plates, quality of lsaw pipe can be tested by non-destructive procedures. while ssaw pipes using hot-rolled coils should be tested with destructive methods such as x-ray.

lsaw pipes adopt welding after molding process where various checks can take place. ssaw pipes employ molding and welding at the same time, pre-checks are not being carried out.