|

Material |

Internal drill or casing slotted pipe material while outside with wire screen jacket. |

|

Application |

Used for sand control in wells with high pressure and high traction value due to the depths. Mainly for petroleum and gas industry. |

Composite sand controlling screen is made of base pipe(drilled or slotted API casing pipe, oil tube, seamless casing spiral or stainless steel casing) and Wedge/V wire screen(Johnson screen). Having the API casing inside a wire wrap screen jacket to support the screen, thus to enhance the capacities and high tensile strength Loads. It is used for sand control in wells with high pressure and high traction value due to the depths.

|

|

Features

1. Structure of wedge wire is not easy to plug, meanwhile, it is easy to backwash; V-shaped profile promises higher sand filtering precision, and hard to plug.

2. Better strength, non-deformability and tensile compressive performance.(Supported by the drilled base pipe inside and different high filter precision fineness wedge/V wire screen outside).

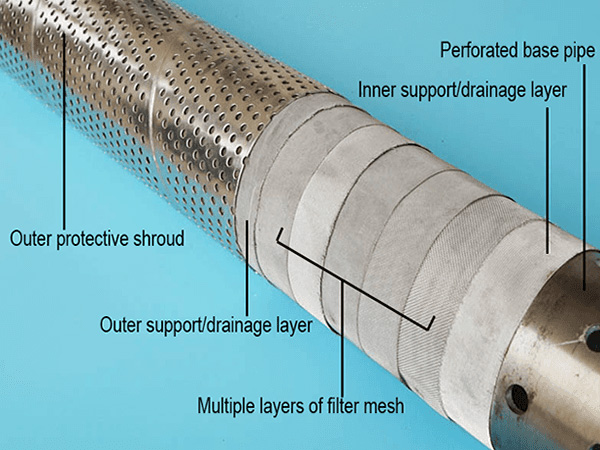

Structure

Base pipe: The base pipe is a perforated pipe that conforms to API standards, which is designed to optimize flow while retaining strength.

Filter jacket: The filter jacket is the core of the sand control mechanism and is engineered to meet the filter requirements. It usually consists of an inner support/drainage layer, multiple layers of filter mesh and an outer support/drainage layer. All these layers are made of metal mesh in forms of plain, twill or dutch woven.

The inner support/drainage layer: It is placed between the base pipe and multiple layers of filter mesh, which provides even distribution of flow between the base pipe and multiple layers of filter mesh and has the function to support multiple layers of filter mesh.

Multiple layers of filter mesh: It is designed to meet the requirements of sand control. A combination of various filter materials can be used to meet different filter requirements to the greatest extent. Its structure can be changeable according to the actual conditions of stratum.

The outer support/drainage layer: It is placed between the filter mesh and the outer protective shroud, which is specially designed for enhancing drainage under the final layer.

Outer protective shroud: The outer protective shroud can be either a perforated pipe or a bridge-type pipe, which protects the filter mesh during deployment and provides support during reverse pressurization.

|

BASE PIPE |

SLIP ON SCREEN JACKET |

|||||||||

|

Nominal Diameter |

Pipe OD (mm) |

Weight |

Hole size |

Holes per foot |

Total |

Screen |

Open area of screen in2/ft |

|||

|

0.008” |

0.012” |

0.015” |

0.020” |

|||||||

|

2-3/8 |

60 |

4.6[4.83] |

3/8 |

96 |

10.60 |

2.86 |

12.68 |

17.96 |

21.56 |

26.95 |

|

2-7/8 |

73 |

6.4[5.51] |

3/8 |

108 |

11.93 |

3.38 |

14.99 |

21.23 |

25.48 |

31.85 |

|

3-1/2 |

88.9 |

9.2[6.45] |

1/2 |

108 |

21.21 |

4.06 |

18.00 |

25.50 |

30.61 |

38.26 |

|

4 |

101.6 |

9.5[5.74] |

1/2 |

120 |

23.56 |

4.55 |

20.18 |

28.58 |

34.30 |

42.88 |

|

4-1/2 |

114.3 |

11.6[6.35] |

1/2 |

144 |

28.27 |

5.08 |

15.63 |

22.53 |

27.35 |

34.82 |

|

5 |

127 |

13[6.43] |

1/2 |

156 |

30.63 |

5.62 |

17.29 |

24.92 |

30.26 |

38.52 |

|

5-1/2 |

139.7 |

15.5[6.99] |

1/2 |

168 |

32.99 |

6.08 |

18.71 |

26.96 |

32.74 |

41.67 |

|

6-5/8 |

168.3 |

24[8.94] |

1/2 |

180 |

35.34 |

7.12 |

21.91 |

31.57 |

38.34 |

48.80 |

|

7 |

177.8 |

23[8.05] |

5/8 |

136 |

42.16 |

7.58 |

23.32 |

33.61 |

40.82 |

51.95 |

|

7-5/8 |

194 |

26.4[8.33] |

5/8 |

148 |

45.88 |

8.20 |

25.23 |

36.36 |

44.16 |

56.20 |

|

8-5/8 |

219 |

32[8.94] |

5/8 |

168 |

51.08 |

9.24 |

28.43 |

40.98 |

49.76 |

63.33 |

|

9-5/8 |

244.5 |

36[8.94] |

5/8 |

188 |

58.28 |

10.18 |

31.32 |

45.15 |

54.82 |

69.77 |

|

10-3/4 |

273 |

45.5[10.16] |

5/8 |

209 |

64.79 |

11.36 |

34.95 |

50.38 |

61.18 |

77.86 |

|

13-3/8 |

339.7 |

54.5[9.65] |

5/8 |

260 |

80.60 |

14.04 |

37.80 |

54.93 |

66.87 |

85.17 |