the steel grades of common oilfield api-5ct casing pipe include j55, k55, n80-1, n80q, and p110. casing pipe is mostly used for oil well drilling.

to understand api casing pipe grades, it is important to understand the terms minimum yield stress, maximum yield stress, and minimum ultimate strength. to explain these terms, two popular grades of oilfield tubulars will be used as an example: l-80 and n-80.

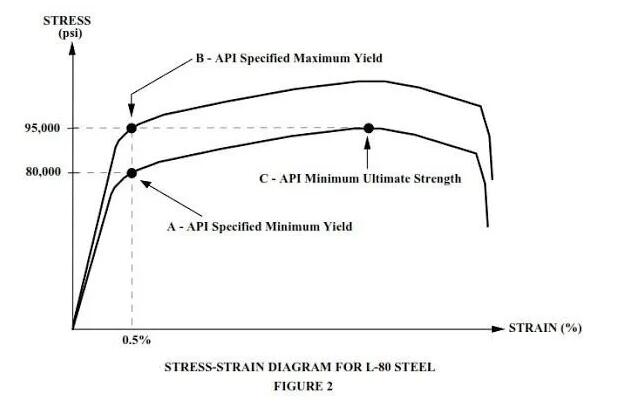

the steel casing pipes grade is denoted by a letter of the alphabet followed by the minimum yield stress of the particular steel. for example, the api p-110 , has a minimum yield stress of 110,000 psi, the api grade l-80, has a minimum yield stress of 80,000 psi as shown by point “a” in figure 2. in other words, it can support a stress of 80,000 psi with an elongation of 0.5%.

the ‘l’ is a distinguishing prefix to avoid confusion between different steel grades. the letter in conjunction with the number designates such parameters as the maximum yield strength and minimum ultimate yield strength.

in l-80 the maximum yield strength is shown by point “b” as 95,000 psi which is 15,000 psi higher than the minimum yield stress. the minimum ultimate strength is shown by point “c” as 95,000 psi. note that there is no maximum ultimate strength specified.

n-80, another api grade (see figure 3), also has a minimum yield stress of 80,000 psi, but is different from l-80 in that the former has a greater maximum yield stress of 110,000 psi (shown by point “b”).

this is 30,000 psi higher than the minimum yield stress and twice the tolerance of l-80. the minimum ultimate strength of 100,000 psi is also higher as shown by point “c”. whereas n-80 has no hardness specification, l-80 has a hardness specification of 23 hrc. the tight tolerance on yield strength and hardness allow the l-80 to be more suitable for h2s service than n-80 grade tubulars.