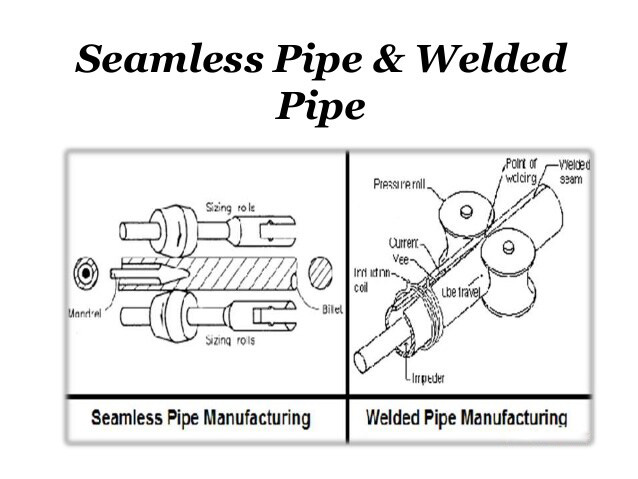

seamless tubing manufacturing

the method of manufacturing welded and seamless tubing is evident in their names alone. seamless tubes are as defined – they do not have a welded seam. the tubing is manufactured through an extrusion process where the tube is drawn from a solid stainless steel billet and extruded into a hollow form. the billets are first heated and then formed into oblong circular molds that are hollowed in a piercing mill. while hot, the molds are drawn through a mandrel rod and elongated. the mandrel milling process increases the molds length by twenty times to form a seamless tube shape. tubing is further shaped through pilgering, a cold rolling process, or cold drawing.

welded tubing manufacturing

a welded steel pipe is produced through roll forming strips or sheets of stainless steel into a tube shape and then welding the seam longitudinally. welded tubing can be accomplished either by hot forming and cold forming processes. of the two, cold forming results in smoother finishes and tighter tolerances. however, each method creates a durable, strong, steel tube that resists corrosion. the seam can be left beaded or it can be further worked by cold rolling and forging methods. the welded tube can also be drawn similar to seamless tubing to produce a finer weld seam with better surface finishes and tighter tolerances.

in addition to the differences in manufacturing processes between seamless pipes and welded pipes, other differences are listed in the following table.

sr. no | parameter | seamless pipe | welded pipe |

1 | raw material | steel billet | hot rolled coil |

2 | strength | able to withstand more pressure and load as there is no weak seam. | due to welding they are believed to withstand 20% less pressure and load as compared to seamless pipe. |

3 | length | relatively shorter in length due to manufacturing difficulties. | can be manufactured in long continuous lengths. |

4 | size | manufactured for nominal size 24 inch or less. | no such size restriction on production. |

5 | wall thickness | inconsistent wall thickness across length, thicker so heavier | wall thickness more consistent than seamless ones, thinner |

6 | corrosion resistance | less prone to corrosion, means more corrosion resistant. | weld areas are more prone to corrosion attacks, means less corrosion resistance. |

7 | surface quality | rough due to extrusion process | smooth high quality surface as compared to seamless pipe. |

8 | economy | costlier | more economic |

9 | production process | complex, long procurement lead time | simpler, short procurement lead time. |

10 | molding process | can be manufactured one time in the rolling process | manufactured with steel strips and plates that weld after bending |

11 | tests | seamless pipes does not require testing for weld integrity. | must be tested before use. |

12 | availability | less available, limited material types, longer delivery time | readily available for various different materials; shorter delivery time |

13 | ovality | better ovality, roundness | poor ovality and roundness as compared to seamless counterpart. |

14 | internal surface check | checking not possible | internal surface can be checked before manufacturing |

15 | welds | no welds | erw, ssaw, lsaw, dsaw |

16 | application | suitable for high presure temperature and corrosive environment | normally used for less corrosive and low pressure environment. |