|

Product: |

Drill Collar, Spiral Drill Collar, OCTG Drill Collars, Steel Drill Collar |

|

Standard |

API SPEC 7-1 |

|

Steel grade: |

AISI 4145H |

|

Sizes: |

3 1/8" -- 11" |

|

Connected Type: |

NC, IF, REG |

|

Type of design: |

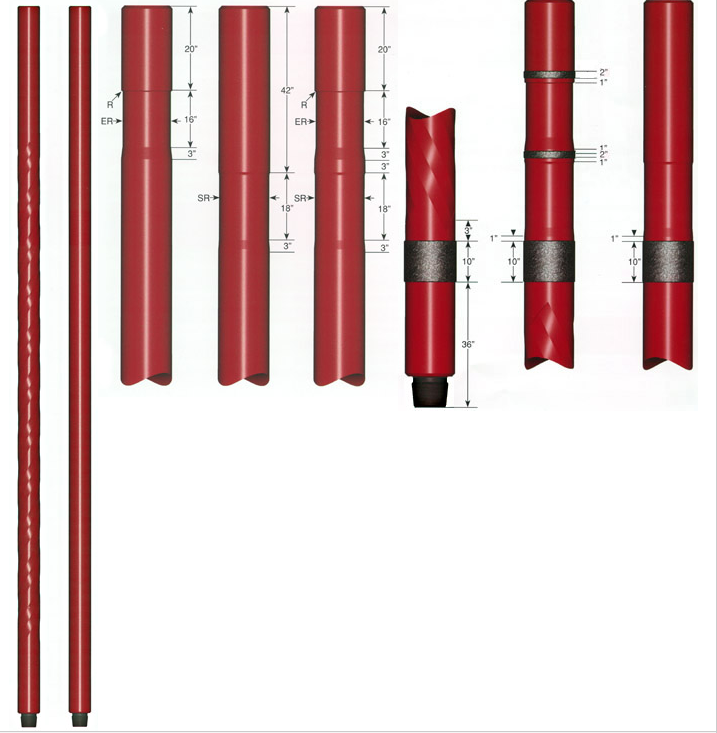

(1)Plain (2)With a recess of the elevator (3)With a recess of the elevator and power slips (4)Spiral and a wide range of type mixtures |

Drill collars are extra-heavy integral tools used to concentrate weight onto the drill bit so as to produce sufficient force for the drill bit to break rock efficiently while drilling. They are made of AISI 4145H modified steel and are connected between drill pipes and drill bits.

Drill collars come in 30 or 31 foot lengths and are furnished as slick (as-rolled surface finish) or spiraled. Spiraled drill collars have grooves on its external surface which maintains an even flow of drilling fluid around the collar to equalize pressure and reduce differential-sticking of the collar to the wall of the oilwell.

Our drill collar connections comply with dimensional requirements specified in API Spec. 7/7-1 and guidelines presented in API RP7G. Drill collars also come with slip and elevator recesses for safe and efficient handling. Slip and elevator recesses can be used together or separately and are machined in compliance with API RP7G guidelines unless otherwise specified.

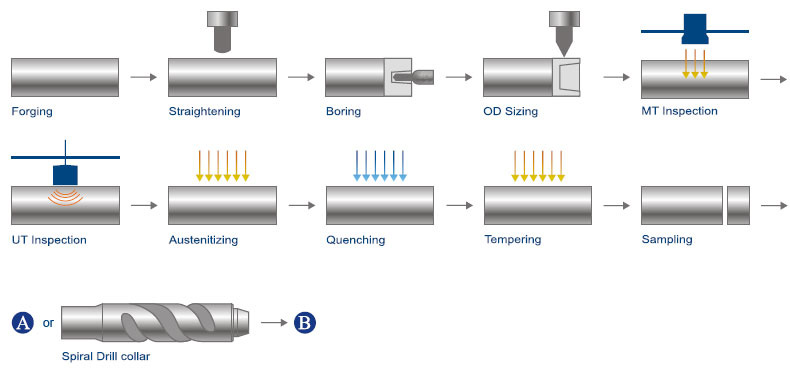

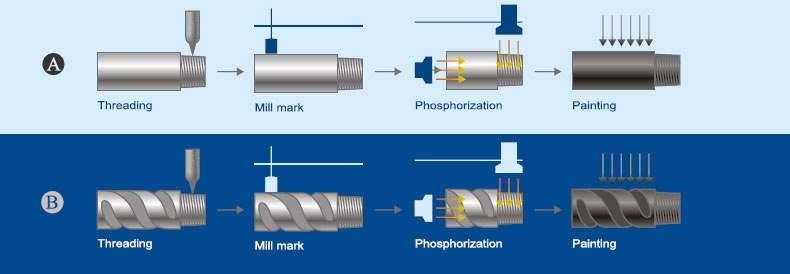

Drill Collar Production Process

|

Standard |

Number |

OD |

ID |

Length |

Weight |

Typical Bending |

|

SY5144-2007/API7-1 |

NC 23-31 |

3-1/8 |

1-1/4 |

30 |

22 |

2.57:1 |

|

NC 26-35 (2-3/8 IF) |

3-1/2 |

1-1/2 |

30 |

27 |

2.42:1 |

|

|

NC 31-41 (2-7/8 IF) |

4-1/8 |

2 |

30 or 31 |

34 |

2.43:1 |

|

|

NC 35-47 |

4-3 /4 |

2 |

30 or 31 |

47 |

2.58:1 |

|

|

NC 38-50 (3-1/2 IF) |

5 |

2-1/4 |

30 or 31 |

54 |

2.38:1 |

|

|

NC 44-60 |

6 |

2-1/4 |

30 or 31 |

83 |

2.49:1 |

|

|

NC 44-60 |

6 |

2-13 /16 |

30 or 31 |

76 |

2.84:1 |

|

|

NC 44-62 |

6-1/4 |

2-1/4 |

30 or 31 |

91 |

2.91:1 |

|

|

NC 46-62 (4 IF) |

6-1/4 |

2-13 /16 |

30 or 31 |

84 |

2.63:1 |

|

|

NC 46-65 (4 IF) |

6-1/2 |

2-1/4 |

30 or 31 |

100 |

2.76:1 |

|

|

NC 46-65 (4 IF) |

6-1/2 |

2-13 /16 |

30 or 31 |

93 |

3.05:1 |

|

|

NC 46-67 (4 IF) |

6-3 /4 |

2-1/4 |

30 or 31 |

109 |

3.18:1 |

|

|

NC 50-70 (4-1/2 IF) |

7 |

2-1/4 |

30 or 31 |

118 |

2.54:1 |

|

|

NC 50-70 (4-1/2 IF) |

7 |

2-13 /16 |

30 or 31 |

111 |

2.73:1 |

|

|

NC 50-72 (4-1/2 IF) |

7-1/4 |

2-13 /16 |

30 or 31 |

120 |

3.12:1 |

|

|

NC 56-77 |

7-3 /4 |

2-13 /16 |

30 or 31 |

140 |

2.70:1 |

|

|

NC 56-80 |

8 |

2-13 /16 |

30 or 31 |

151 |

3.02:1 |

|

|

6-5/8 API Reg |

8-1/4 |

2-13 /16 |

30 or 31 |

162 |

2.93:1 |

|

|

NC 61-90 |

9 |

2-13 /16 |

30 or 31 |

196 |

3.17:1 |

|

|

7-5/8 API Reg |

9-1/2 |

3 |

30 or 31 |

217 |

2.81:1 |

|

|

NC 70-97 |

9-3 /4 |

3 |

30 or 31 |

230 |

2.57:1 |

|

|

NC 70-100 |

10 |

3 |

30 or 31 |

243 |

2.81:1 |

|

|

8-5/8 API Reg |

11 |

3 |

30 or 31 |

300 |

2.84:1 |

Drill collars are integral heavy-duty joints that are constructed from a solid bar of AISI 4145H modified alloy steel. Our standard drill collars are supplied with an “as rolled” surface finish condition. All standard bars receive heat treatment that provides them with the necessary mechanical properties.

The bars are then trepanned and drifted. All of our drill collars are manufactured by API spec 7, Q1, and recommended practice 7G, as applicable.

Standard Sizes, Bores, and Connections

|

Drill Collar Conn. Size & Type |

Min. OD |

Bore | Length |

Bending Strength Ratio*** |

Drill Collar Wt. |

| (in.) | (in.) | (ft.) | (lb.) | ||

| NC 26 (2-3/8 IF) |

3-1/2 |

1-1/2 | 30 | 2.42:1 | 801 |

| NC 31 (2-7/8 IF) | 4-1/8 | 2 | 30 | 2.43:1 | 1041 |

| NC 38 (3-1/2 IF) | 4-3/4 | 2-1/4 | 31 | 1.85:1 | 1451 |

| NC 38 (3-1/2 IF) | 5 | 2-1/4 | 31 | 2.38:1 | 1652 |

| NC 44 | 6 | 2-1/4 | 31 | 2.49:1 | 2561 |

| NC 44 | 6 | 2-13/16 | 31 | 2.84:1 | 2353 |

| NC 44 | 6-1/4 | 2-1/4 | 31 | 2.91:1 | 2806 |

| NC 46 (4 IF) | 6-1/4 | 2-13/16 | 31 | 2.63:1 | 2598 |

| NC 46 (4 IF) | 6-1/2 | 2-1/4 | 31 | 2.76:1 | 3085 |

| NC 46 (4 IF) | 6-1/2 | 2-13/16 | 31 | 3.05:1 | 2877 |

| NC 46 (4 IF) | 6-3/4 | 2-1/4 | 31 | 3.18:1 | 3364 |

| NC 50 (4-1/2 IF) | 7 | 2-1/4 | 31 | 2.54:1 | 3643 |

| NC 50 (4-1/2 IF) | 7 | 2-13/16 | 31 | 2.73:1 | 3434 |

| NC 50 (4-1/2 IF) | 7-1/4 | 2-13/16 | 31 | 3.12:1 | 3714 |

| NC 56 | 8 | 2-13/16 | 31 | 3.02:1 | 4675 |

| 6-5/8 REG. | 8 | 2-13/16 | 31 | 2.60:1 | 4675 |

| 6-5/8 REG. | 8-1/4 | 2-13/16 | 31 | 2.93:1 | 5016 |

| 7-5/8 REG. | 9-1/2 | 3 | 31 | 2.81:1 | 6727 |

| 7-5/8 REG.** | 9-3/4 | 3 | 31 | 3.09:1 | 7130 |

| 8-5/8 REG.** | 11 | 3 | 30 | 2.78:1 | 8970 |

|

** Low torque face *** Ratio of box to pin section modulus – See API RP7G for details Note: Other sizes and connections are available as well as any other optional features listed |

|||||

| Mechanical Property | ||||||

| TTT |

Yield strength 0.2Mpa |

Tensile strength b Mpa |

Elongation 4% |

Hardness(Brinell) |

IMPACT VALUE(CHAPPY-V) |

|

| mm |

in inch |

|||||

| 79.4-171.4 |

3 1/8-6 3/4 |

≥ 758 |

≥ 965 |

≥ 13 |

285-341 |

≥ 54 |

| 177.8-279.4 |

7-11 |

≥ 689 |

||||