|

Type |

Spiral wound gasket, ring joint gasket |

|

Pressure-temperatures classes |

Class 150 to 2500 |

|

Standards |

ASME B 16.20, BS 3381 |

|

Materials |

Low carbon steel, 4-6% Chrome, ½ Mo, Stainless steel |

Metal Gasket / Ring Joint Gasket / RTJ Gasket

Metal gaskets are manufactured from a material such as Soft iron, Low Carbon steel, Stainless Steel, Monel, and Inconel. These gaskets are also known as ring gasket or RTJ gaskets.

Metallic gaskets are used in high-pressure class flanges, normally above 900 Class, they can also be used for high-temperature

High tension bolting is required when we used metallic gaskets.

They are very robust & most costly.

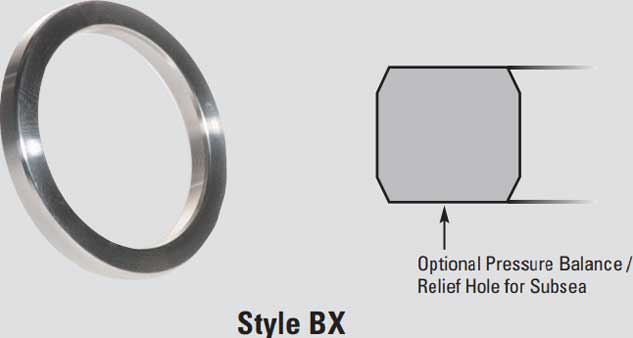

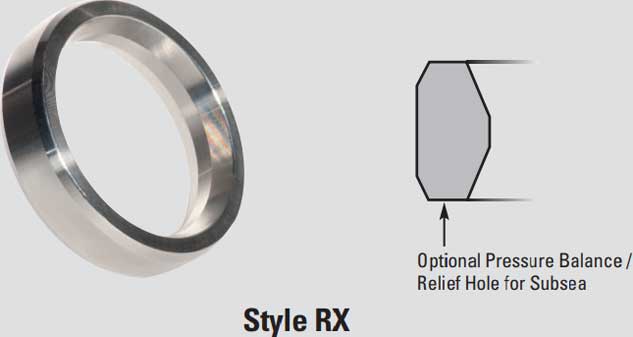

The RTJ Gasket fits in a groove machined on the flange face of both mating flanges. There are two types of the metallic gasket are used with RTJ flange Octagonal and Oval. You can see the difference in their cross-section view.

Spiral wound gasket (SWG)

Spiral Wound Gasket comprise a mix of metallic and filler material. Generally, the gasket has a metal (normally carbon rich or stainless steel) wound outwards in a circular spiral (other shapes are possible) with the filler material (generally a flexible graphite) wound in the same manner but starting from the opposing side.

Spiral Wound Gasket is widely applied in the fields of petrochemical, mechanical factory, power station, metallurgy, shipbuilding, medical and pharmaceutical unclear power station and navigation, etc.