|

Product |

Low Temperature Pipe, ASTM A333 Tube, A333 Steel Pipe |

|

Application |

In Refineries, Power Plants, Boilers, Heat Exchangers, Condensers etc. |

|

Pipe Standard |

ASTM A333/ASME SA333 |

|

Size |

OD: 73-630mm |

|

|

WT: 6-35mm |

|

|

Length: Single Random, Double Random, Cut Length |

|

Surface |

Pickling or shot blasting, Passivated, Black Phosphating |

|

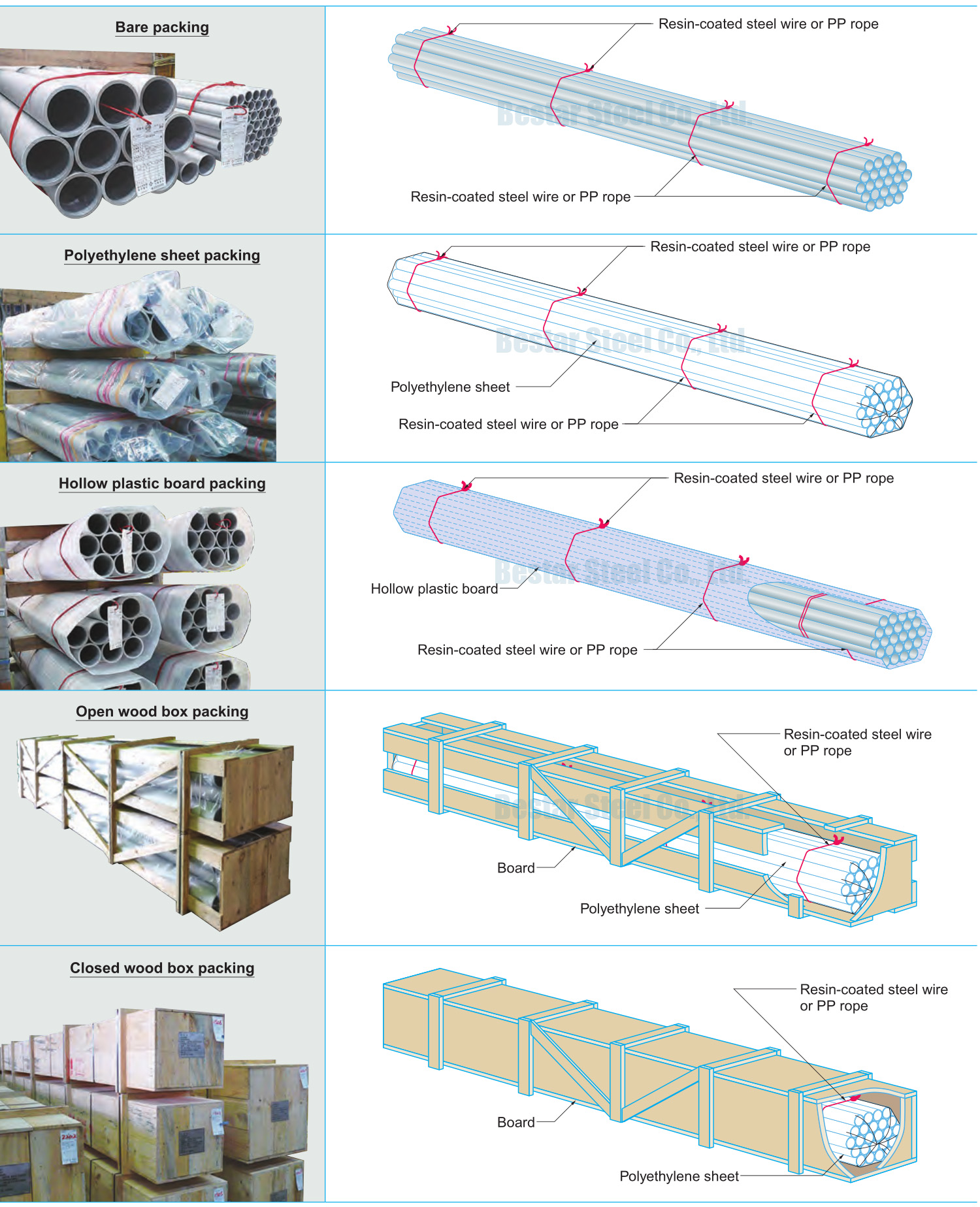

Packing |

Weaving Bag, Seaworthy Bundles, Wooden Case if required |

A seamless low-temperature carbon steel pipe is a pipe that does not have a welding seam or a welding joint.

A welded low-temperature carbon steel pipe is a steel pipe that is formed by rolling a steel plate and welding the seam.

ASTM A333 (ASME S/A-333) Pipe grades permit low-temperature service. This specification covers nominal (average) walled pipe almost exclusively in seamless. Several grades of ferritic steel are included.

Some product sizes may not be available under this specification because heavier wall thicknesses have an adverse effect on low-temperature impact properties.

A333 pipe is furnished to nine different grades designated by numbers 1, 3, 4, 6, 7, 8, 9, 10, & 11.

LTCS (Low Temperature Carbon Steel) is used in piping system when there is a possibility of process fluid temperature falling below -20°F during operation.

Low-temperature carbon steels have been chiefly used in low-temperature equipment such as chemical plant below -55 °F and especially for welded pressure vessels.

Standard Specifications for LTCS Pipes and Tubes

Specifications- ASTM A333/ ASME SA333

Standard- ASTM, ASME and API

Size- 1/2 '' - 24''

Schedule- SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All schedules

Types- Seamless/ ERW/ Welded/ Fabricated/ CDW

Length- Single Random, Double Random, and Required length, Custom size- 12 meters

Form- Round Pipes/ Tubes, Square pipes/ tubes, Square pipes/ tubes, Coiled tubes, U Shape, Pancake coils, Hydraulic tubes

End- Plain End, Beveled End, Threaded

Grades- ASTM A333 Grade1, ASTM A333 Grade 3, ASTM A333 Grade 6, ASTM A334 Grade 1, ASTM A334 Grade 6.

Application of LTCS

They can be found in heat exchangers, chemical containers, pipelines and throughout the food industry.

It can be used as a fabricated material where high-temperature petroleum gases or steam production gases are stored such as pressure vessel

Benefits of LTCS

Low carbon content eliminates carbon precipitation in the welding process

It can be used in severe corrosive environments

Weld annealing is only required in high-stress applications

1. ASTM A333 Chemical Composition Requirements

|

Chemical Composition of ASTM A333 |

|||||||||

|

Element |

Grade 1, % |

Grade 3, % |

Grade 4, % |

Grade 6, % |

Grade 7, % |

Grade 8, % |

Grade 9, % |

Grade 10, % |

Grade 11, % |

|

C |

0.30 |

0.19 |

0.12 |

0.30 |

0.19 |

0.13 |

0.20 |

0.20 |

0.10 |

|

Mn |

0.40–1.06 |

0.31–0.64 |

0.50–1.05 |

0.29–1.06 |

0.90 |

0.90 |

0.40–1.06 |

1.15–1.50 |

0.60 |

|

P |

0.025 |

0.025 |

0.025 |

0.025 |

0.025 |

0.025 |

0.025 |

0.035 |

0.025 |

|

S |

0.025 |

0.025 |

0.025 |

0.025 |

0.025 |

0.025 |

0.025 |

0.015 |

0.025 |

|

Si |

... |

0.18–0.37 |

0.08–0.37 |

0.10 min |

0.13–0.32 |

0.13–0.32 |

... |

0.10–0.35 |

0.35 |

|

Ni |

... |

3.18–3.82 |

0.47–0.98 |

0.40 |

2.03–2.57 |

8.40–9.60 |

1.60–2.24 |

0.25 |

35.0–37.0 |

|

Cr |

... |

... |

0.44–1.01 |

0.30 |

... |

... |

... |

0.15 |

0.50 |

|

Cu |

... |

... |

0.40–0.75 |

0.40 |

... |

... |

0.75–1.25 |

0.15 |

... |

|

Al |

... |

... |

0.04–0.30 |

... |

... |

... |

... |

0.06 |

... |

|

V |

... |

... |

... |

0.08 |

... |

... |

... |

0.12 |

... |

|

Cb |

... |

... |

... |

0.02 |

... |

... |

... |

0.05 |

... |

|

Mo |

... |

... |

... |

0.12 |

... |

... |

... |

0.05 |

0.50 |

|

Co |

... |

... |

... |

... |

... |

... |

... |

... |

0.50 |

*For Grade 1 and 6, each reduction of 0.01% C below 0.30%, an increase of 0.05 % Mn above 1.06 % would be permitted to a max. of 1.35%.

*For Grade 6, the limit for columbium may be increased up to 0.05 % on heat analysis and 0.06 % on product analysis.

*Generally, the carbon equivalent C.E = [C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15] shall not exceed 0.43% by heat analysis.

2. ASTM A333 Mechanical Properties

|

ASTM A333 |

Tensile Strength, min. |

Yield Strength, min. |

Elongation %, min. |

|||

|

Grade |

psi |

MPa |

psi |

MPa |

Longitudinal |

Transverse |

|

Grade 1 |

55 000 |

380 |

30 000 |

205 |

35 |

25 |

|

Grade 3 |

65 000 |

450 |

35 000 |

240 |

30 |

20 |

|

Grade 4 |

60 000 |

415 |

35 000 |

240 |

30 |

16.5 |

|

Grade 6 |

60 000 |

415 |

35 000 |

240 |

30 |

16.5 |

|

Grade 7 |

65 000 |

450 |

35 000 |

240 |

30 |

22 |

|

Grade 8 |

100 000 |

690 |

75 000 |

515 |

22 |

... |

|

Grade 9 |

63 000 |

435 |

46 000 |

315 |

28 |

... |

|

Grade 10 |

80 000 |

550 |

65 000 |

450 |

22 |

... |

|

Grade 11 |

65 000 |

450 |

35 000 |

240 |

18 |

... |

*The elongation values are furnished on the basis of standard round 2 inch or 50 mm(or 4D) specimens.

*Elongation of Grade 11 is for all walls and small sizes tested in full section.

3. Charpy V-notch Impact Tests

|

Impact Requirements for Grades 1, 3, 4, 6, 7, 9, 10, and 11 |

||||

|

Size of Specimen |

*A |

*B |

||

|

mm |

ft·lbf |

J |

ft·lbf |

J |

|

10 by 10 |

13 |

18 |

10 |

14 |

|

10 by 7.5 |

10 |

14 |

8 |

11 |

|

10 by 6.67 |

9 |

12 |

7 |

9 |

|

10 by 5 |

7 |

9 |

5 |

7 |

|

10 by 3.33 |

5 |

7 |

3 |

4 |

|

10 by 2.5 |

4 |

5 |

3 |

4 |

*A denotes minimum average notched bar impact value of each set of three specimens.

*B denotes minimum notched bar impact value of one specimen only of a set.

|

Minimum Impact Test Temperature of ASTM A333 |

||

|

Grade |

°F |

°C |

|

1 |

-50 |

-45 |

|

3 |

-150 |

-100 |

|

4 |

-150 |

-100 |

|

6 |

-50 |

-45 |

|

7 |

-100 |

-75 |

|

8 |

-320 |

-195 |

|

9 |

-100 |

-75 |

|

10 |

-75 |

-60 |

|

11 |

-320 |

-195 |

* Impact tests specified for temperatures lower than 70 °F [20 °C] should be made with precautions.

|

NPS |

Outside Diameter |

ASTM A333 Grade 6 Carbon Steel Seamless Pipes Schedule |

||||||||||||

|

|

|

SCH 10 |

SCH 20 |

SCH 30 |

SCH STD |

SCH 40 |

SCH 60 |

SCH XS |

SCH 80 |

SCH 100 |

SCH 120 |

SCH 140 |

SCH 160 |

SCH XXS |

|

|

|

Wall Thickness (in) |

||||||||||||

|

1/8 |

0.405 |

|

|

|

0.068 |

0.068 |

|

0.095 |

0.095 |

|

|

|

|

|

|

1/4 |

0.540 |

|

|

|

0.088 |

0.088 |

|

0.119 |

0.119 |

|

|

|

|

|

|

3/8 |

0.675 |

|

|

|

0.091 |

0.091 |

|

0.126 |

0.126 |

|

|

|

|

|

|

1/2 |

0.840 |

|

|

|

0.109 |

0.109 |

|

0.147 |

0.147 |

|

|

|

0.187 |

0.294 |

|

3/4 |

1.050 |

|

|

|

0.113 |

0.113 |

|

0.154 |

0.154 |

|

|

|

0.219 |

0.308 |

|

1 |

1.315 |

|

|

|

0.133 |

0.133 |

|

0.179 |

0.179 |

|

|

|

0.250 |

0.358 |

|

1 1/4 |

1.660 |

|

|

|

0.140 |

0.140 |

|

0.191 |

0.191 |

|

|

|

0.250 |

0.382 |

|

1 1/2 |

1.900 |

|

|

|

0.145 |

0.145 |

|

0.200 |

0.200 |

|

|

|

0.281 |

0.400 |

|

2 |

2.375 |

|

|

|

0.154 |

0.154 |

|

0.218 |

0.218 |

|

|

|

0.344 |

0.436 |

|

2 1/2 |

2.875 |

|

|

|

0.203 |

0.203 |

|

0.276 |

0.276 |

|

|

|

0.375 |

0.552 |

|

3 |

3.500 |

|

|

|

0.216 |

0.216 |

|

0.300 |

0.300 |

|

|

|

0.438 |

0.600 |

|

3 1/2 |

4.000 |

|

|

|

0.226 |

0.226 |

|

0.318 |

0.318 |

|

|

|

|

|

|

4 |

4.500 |

|

|

|

0.237 |

0.237 |

|

0.337 |

0.337 |

|

0.438 |

|

0.531 |

0.674 |

|

5 |

5.563 |

|

|

|

0.258 |

0.258 |

|

0.375 |

0.375 |

|

0.500 |

|

0.625 |

0.750 |

|

6 |

6.625 |

|

|

|

0.280 |

0.280 |

|

0.432 |

0.432 |

|

0.562 |

|

0.719 |

0.864 |

|

8 |

8.625 |

|

0.250 |

0.277 |

0.322 |

0.322 |

0.406 |

0.500 |

0.500 |

0.594 |

0.719 |

0.812 |

0.906 |

0.875 |

|

10 |

10.750 |

|

0.250 |

0.307 |

0.365 |

0.365 |

0.500 |

0.500 |

0.594 |

0.719 |

0.844 |

1.000 |

1.125 |

1.000 |

|

12 |

12.750 |

|

0.250 |

0.330 |

0.375 |

0.406 |

0.562 |

0.500 |

0.688 |

0.844 |

1.000 |

1.125 |

1.312 |

1.000 |

|

14 |

14.000 |

0.250 |

0.312 |

0.375 |

0.375 |

0.438 |

0.594 |

0.500 |

0.750 |

0.938 |

1.094 |

1.250 |

1.406 |

|

|

16 |

16.000 |

0.250 |

0.312 |

0.375 |

0.375 |

0.500 |

0.656 |

0.500 |

0.844 |

1.031 |

1.219 |

1.438 |

1.594 |

|

|

18 |

18.000 |

0.250 |

0.312 |

0.438 |

0.375 |

0.562 |

0.750 |

0.500 |

0.938 |

1.156 |

1.375 |

1.562 |

1.781 |

|

|

20 |

20.000 |

0.250 |

0.375 |

0.500 |

0.375 |

0.594 |

0.812 |

0.500 |

1.031 |

1.281 |

1.500 |

1.750 |

1.969 |

|

|

22 |

22.000 |

0.250 |

0.375 |

0.500 |

0.375 |

|

0.875 |

0.500 |

1.125 |

1.375 |

1.625 |

1.875 |

2.125 |

|

|

24 |

24.000 |

0.250 |

0.375 |

0.562 |

0.375 |

0.688 |

0.969 |

0.500 |

1.219 |

1.531 |

1.812 |

2.062 |

2.344 |

|

|

30 |

30.000 |

0.312 |

0.500 |

0.625 |

0.375 |

|

|

0.500 |

|

|

|

|

|

|

|

32 |

32.000 |

0.312 |

0.500 |

0.625 |

0.375 |

0.688 |

|

|

|

|

|

|

|

|

|

34 |

34.000 |

0.312 |

0.500 |

0.625 |

0.375 |

0.688 |

|

|

|

|

|

|

|

|

|

36 |

36.000 |

0.312 |

0.500 |

0.625 |

0.375 |

0.750 |

|

|

|

|

|

|

|

|

|

42 |

42.000 |

|

0.500 |

0.625 |

0.375 |

0.750 |

|

|

|

|

|

|

|

|

|

A333 |

Standard Specification for Seamless and Welded Steel Pipe for Low-Temperature Service |