electric resistance welded (erw) pipe is manufactured by cold forming a flat steel strip into a rounded tube and passing it through a series of forming rollers to obtain a longitudinal seam. the two edges are then simultaneously heated with a high frequency current and squeezed together to form a bond. the longitudinal erw seam does not require filler metal.

usually erw pipe maximum od is 24" (609mm), for larger dimensions pipe will be manufactured in saw.

a few advantages to note with erw pipe:

there are no fusion metals used during the manufacturing process. this means that the pipe is extremely strong and durable.

the weld seam cannot be seen or felt. this is a major difference when looking at the double submerged arc welding process, which creates an obvious welded bead that might need to be eliminated.

with the advances in high-frequency electric currents for welding, the process is far easier and safer.

|  |  |  |

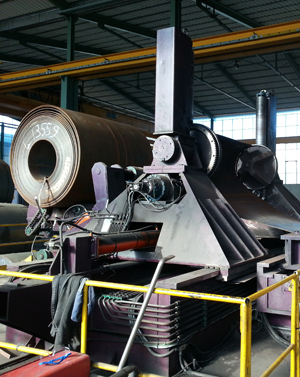

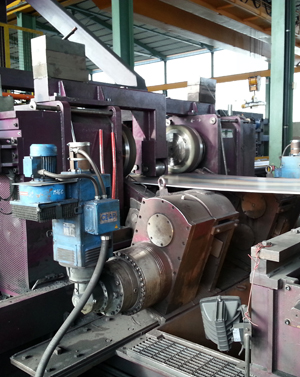

uncoiling & flattening incoming coils are peeled and unwrapped for presentation into the flattener rolls. flattening removes the coil set to produce a flat steel strip. | coil joining coil ends are joined together with a butt weld to produce a continuous strip. | edge trimming slitter blades and edge milling trims strip edges to provide the precise strip width required during the forming and erw seam welding process. | forming the forming process begins at the breakdown pass where the material is gradually bent from a flat steel strip into a rounded tube for presentation to the erw seam welder. |

|  |  |  |

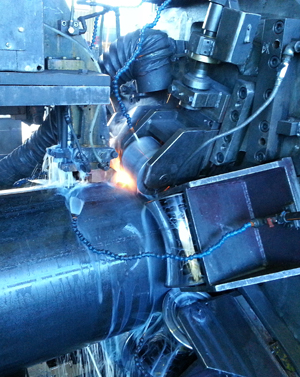

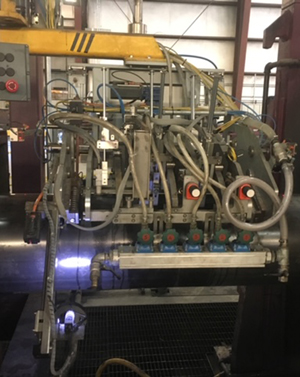

welding a high frequency electrical current flows through contact tips into the strip edges to produce the heat required for bonding the strip edges together as the material passes through the weld roll stand. | quality control once the welding is complete, the finished pipe is visually inspected by quality control (qc) and, if required, ultrasonic (ut) testing is performed to ensure the weld is defect-free. | pipe sizing/straightening the sizing section squeezes the welded pipe into the precise roundness, outer diameter, and straightness tolerances specified by the customer. | pipe cutting the flying cut-off saw attaches to the pipe as it is being produced and cuts the pipe to the length specified by the customer. |

there are a lot of pipes could be manufactured by erw process. here below we list for the most common standards in pipelines.

carbon steel pipe in erw

astm a53 grade a and b (and galvanized)

astm a252 pile pipe

astm a500 structural tubing

astm a134 and astm a135 pipe

en 10219 s275, s355 pipe

stainless steel erw pipe

astm a269 stainless pipe

astm a270 sanitary tubing

astm a312 stainless pipe

astm a790 ferritic/austenitic/duplex stainless pipe

api erw line pipe

api 5l b to x70 psl1 (psl2 shall be in hfw process)

api 5ct j55/k55, n80 casing and tubing

and etc.

bestar steel is professional erw pipe manufacturer. if you need a quotation of our products or have any questions, please contact us.