|

Product |

Well casing, API 5CT Casing, API 5CT Casing Pipe |

|

Application |

Oil well casing serves as well sidewall |

|

Pipe Standard |

API SPEC 5CT |

|

Size |

OD: 114.3-508mm |

|

|

WT: 5.21-16.13mm |

|

Thread types |

STC, LTC, BTC, special clearance, premium connection |

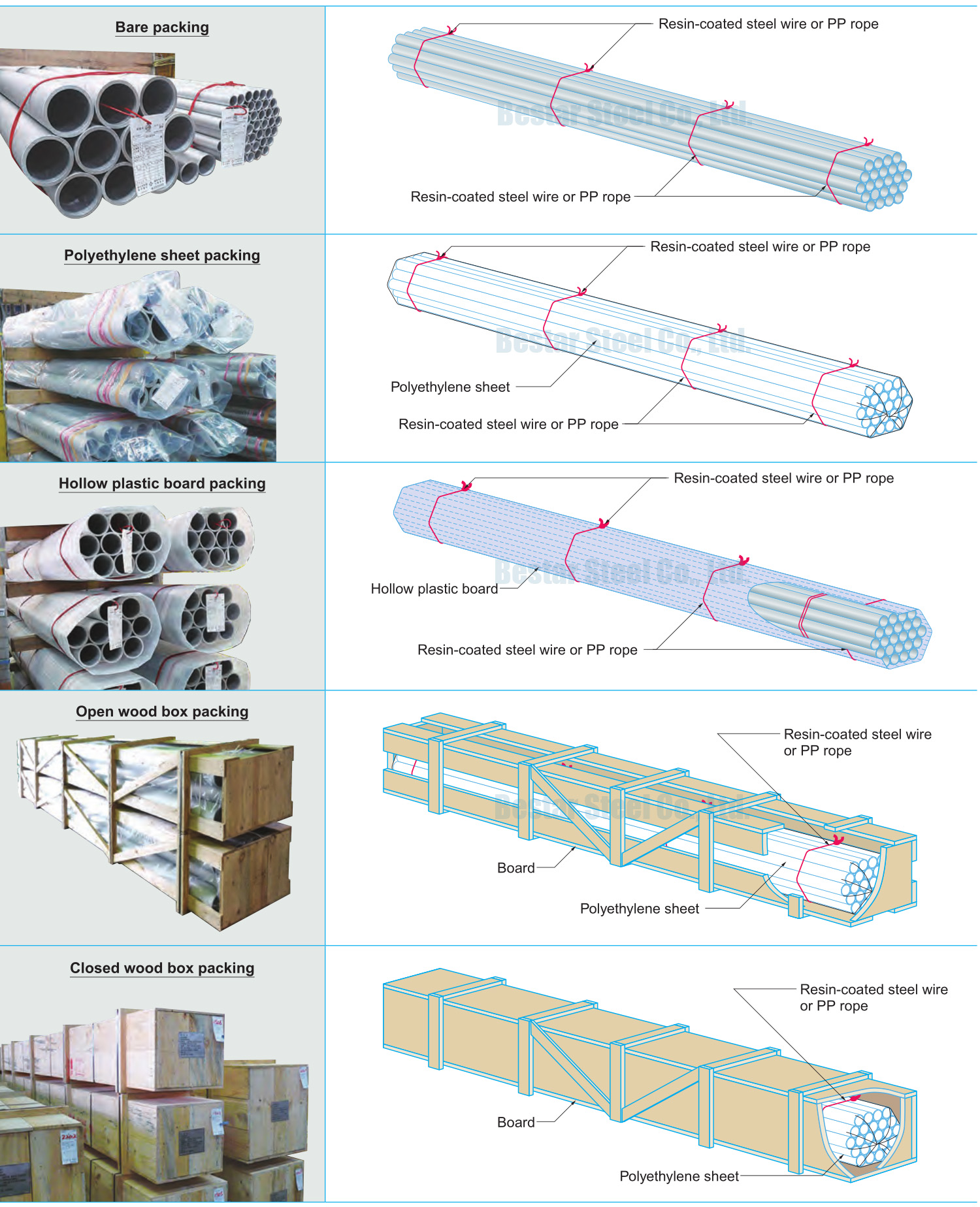

| Packing: |

Protection Caps in Both Ends, Waterproof Paper Wrapped, Two Tags |

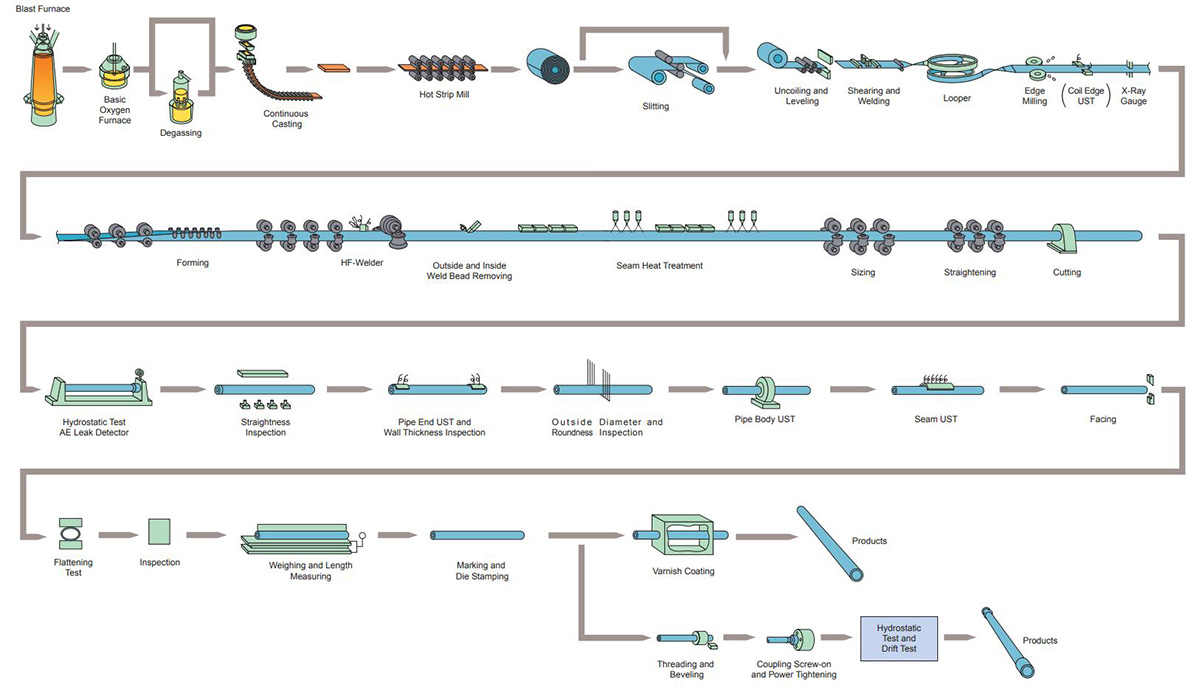

What is API 5CT casing ?

API SPEC 5CT well casing is utilized in fixing the well wall or down hole, which has wider diameters. API SPEC 5CT can be divided into conductor casing, technical casing and oil casing.

API 5CT is standard technical specifications for steel casing pipes used for oil wells in petroleum and natural gas industries.

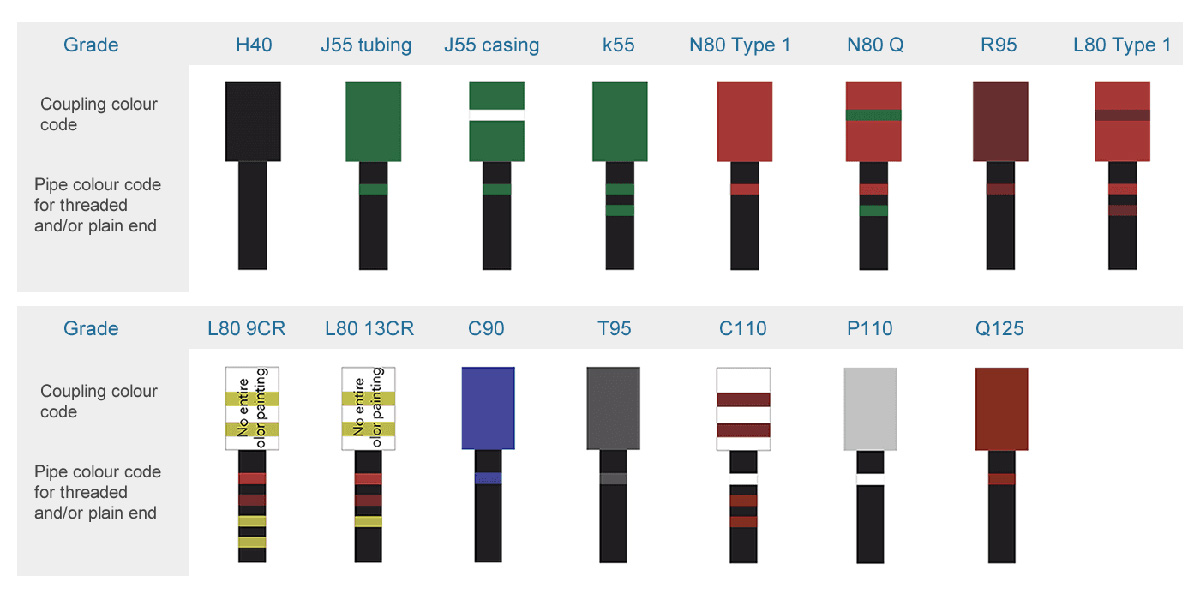

Common Grades

• J55/K55

• N80/N80Q/L80

• C90

• R95/T95

• P110/C110

• Q125

Connections

API 5CT is applicable to following connections which complied with API SPEC 5B:

• SC: Short round thread casing

• LC: Long ound thread casing

• BC: Buttress thread casing

• NU: Non-upset tubing

• EU: External upset tubing

• IJ: Integral tubing connections

More casing pipes and their colors

Lengths:

Dimension:

Mechanical Properties: