2023-10-13

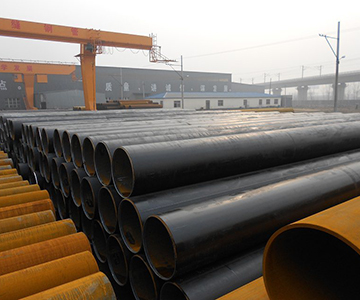

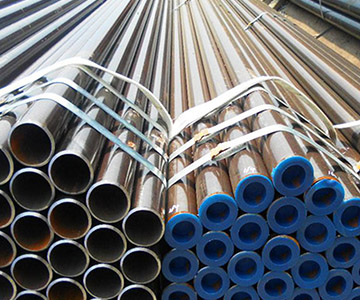

1) Steel pipe inspection: The plastic-coated water supply steel pipes, pipe fittings, and interface materials entering the site must have the product certificate and performance test report of the manufacturer, and undergo visual inspection. The test data should comply with the specifications. Damaged and substandard products are strictly prohibited from use.

2) On-site pipe laying: On-site pipe laying is carried out by crane. The pipe laying should be based on the drawing requirements and the dug pipe trenches. Pipes should be laid one by one, connected end to end, and two adjacent pipe openings should be staggered in a zigzag shape. Each pipe should be lifted off the ground with a soft mound or sandbag and cannot be placed directly on the ground. Special rigging is used for pipe laying. Special attention should be paid to protecting the insulation layer and pipe openings of pipe sections during on-site pipe laying. Dragging, rolling, and prying methods are not allowed to lay pipes. During the hauling process, measures should be taken to prevent damage to the pipes to avoid damaging or scratching the pipes and the outer anti-corrosion layer. Repair and eliminate defects such as grooves and scratches on the surface of the pipe.

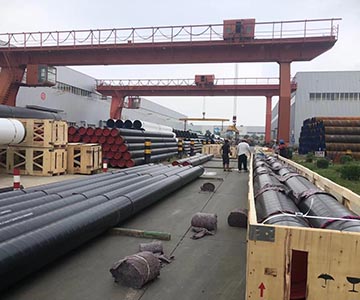

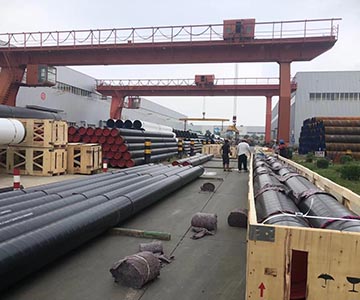

3) Hoisting and transportation of epoxy resin powder-coated steel pipes

(3.1) The pipeline is transported by a 40T semi-trailer and hoisted by a sling with a width of not less than 150mm. When loading and unloading, it should be lifted gently and placed firmly to prevent collisions and damage to the protective layer.

(3.2) The pipes are stacked on square logs and wedged tightly, with a height not exceeding 2m. They should be placed together with the specifications, and the quantity of the specifications should be marked. The pipe ends should be sealed to prevent debris from entering.

(3.3) According to the actual conditions on site, a 25T truck crane is used for pipe hoisting, and a nylon sling and a wire rope hook are used together to lower the pipes one by one. In some areas, pipes need to be threaded to put the pipes in place.

4) Epoxy resin powder-coated steel pipe assembly

(4.1) Pipe processing: cut to length according to the required length. After measuring the required length, use an electric saw to cut it. After checking the length, use an oxygen-acetylene flame to cut the line, process the bevel, and polish it with a polisher.

(4.2) Before connecting the pipes, clear the debris in the pipes and seal them with blocking plates when stopping work to reduce the workload of pipe flushing. Before welding, the oil stains and other debris on the pipe mouth should be polished away to expose the metallic luster.

(4.3) Use steel pipe cross arms and inverted chains for the pipes, and install them one by one from the starting point of each construction section. After assembly, measure the elevation and centerline of the pipes, and adjust them one by one so that the center offset of each 10m pipe is ≯5mm, the pipe center elevation deviation is ≯10mm, and the coordinate deviation is ≯25mm.

(4.4) When connecting pipes, do not use strong force to connect the joints, heat the pipes, add offset pads or layered pads, etc. to eliminate gaps, deviations, misalignment, or non-concentric defects on the interface end faces.

5) Requirements for welds when matching epoxy resin powder-coated steel pipes:

a. The distance between the two ring welds of the straight pipe section shall not be less than 2m.

b. The longitudinal welds of the pipes should be staggered, with a spacing of not less than 200mm.

6) Welding of epoxy resin powder-coated steel pipes: The pipe material of this project is plastic-coated steel pipes for water supply. The welding method is manual arc welding. The welding rods are E43 series and the welding machine is BX-500 AC welding machine.

7) Pipe installation

⑴ When cutting steel pipes, use acetylene to remove the heat-affected zone on the cutting surface. Its thickness is generally not less than 0.5mm.

⑵The quality of pipe cuts should meet the following requirements:

a. The incision surface should be smooth, without cracks, heavy skin, burrs, unevenness, shrinkage, slag, iron oxide, iron filings, etc., and should be removed.

b. The perpendicularity between the incision plane and the pipe axis shall not exceed 1% of the pipe diameter and shall not be greater than 2mm.

⑶The position of pipeline welding joints should meet the following requirements:

A. The distance between two adjacent welds shall not be less than 1.5 times the nominal diameter of the long pipe, and shall not be less than 150mm.

B. The clear distance between the pipeline welding joint and the buttress shall not be less than 50mm, and the distance between the welding seam requiring heat treatment and the buttress shall not be less than 300mm.

C. No holes are allowed in the pipeline welds.

D. The distance between the pipe butt weld and the starting point of the elbow shall not be less than 100mm, and shall not be smaller than the outer diameter of the pipe.

E. The straight welds of straight seam pipes should be located where they are easy to inspect and repair, and should not be at the bottom.

⑷ Before assembling the pipeline, the bevel and its internal and external surfaces should be cleaned manually or mechanically to remove dirt, oil, paint, rust, burrs, etc. within 100mm of the edge of the pipeline. Temporary seals should be added to both ends of the pipe being installed before the end of the work. Blind board.

(5) The misalignment of pipe docking is ±2mm, leaving a gap of 2.5~3mm.