|

Product: |

Tubing Pipe, Oil Tubing, API Tubing Well Tubing, Tubing |

|

Application: |

Used for extracing Oil or Gas from Wells |

|

Size: |

OD: 48.26mm-114.3mm |

|

|

WT: 3.18-16mm |

|

|

LENGTH: R1, R2, R3 |

|

Pipe Standard: |

API 5CT PSL1/PSL2 J55,K55,N80-1,N80-Q, |

|

|

API 5CT PSL1/PSL2 L80-1, L80-9Cr,L80-13Cr,C90, C95, P110, Q125 |

|

Thread: |

NUE, EUE, STC, LTC, BTC, premium connection |

|

Special Service |

Sweet Service, Sour Service, Anti-H2S, NACE MR0175/ISO15156 |

|

Accessories: |

Pup Joint, Coupling, Drill Collar, Crossover etc. |

Tubing is a relatively small-diameter pipe that is run into a well to serve as a conduit for the passage of oil and gas to the field surface facilities for processing. Tubing must be adequately strong to resist loads and deformations associated with production and workovers. Further, tubing must be sized to support the expected rates of production of oil and gas.

Tubing Specifications:

Tubing is specified by grade, outer diameter, weight, and connection. API tubing grades correspond to casing grades with the exception that P grade tubing has a tensile strength of 105,000 psi and is referred to as P105.

Tubing comes with non-upset (NUE) and external upset (EUE) ends. EUE tubing is more common, because of the benefit that cutting threads into the tubing ends does not reduce the body strength.

NB: for ESP applications, if power cable clearance between the tubing and casing becomes an issue, NUE tubing should be considered.

Internal diameter (ID): is a result of the OD and the wall thickness, and it is used to calculate pressure losses and velocities.

The drift diameter: is the diameter of a 42” long mandrel that passes through tubing joint. It is a foremost parameter as it gives the maximum OD of any equipment to run through the tubing string.

Maximum outside diameter: it depends on the nominal diameter and the connection type. It is critical as it determines the strings size that we can run in a given casing.

Nominal size: is the outside diameter of the pipe body. The most used sizes are: 2-⅜”, 2-⅞”, 3-½” and 4-½”.

The tubing joint length: is the length of tubing joint including the coupling and excluding the pin thread. It is classified into two length range: range I: from 20 ft to 24 ft (6.1 to 7.32 m) long, or range II: from 28 ft to 32 ft (8.53 to 9.75 m) long. The length range must be chosen with care. It must be compatible with the hoisting and storage capacity of the mast of the rig used when running in hole the equipment during completion as well as later on during workover operations.

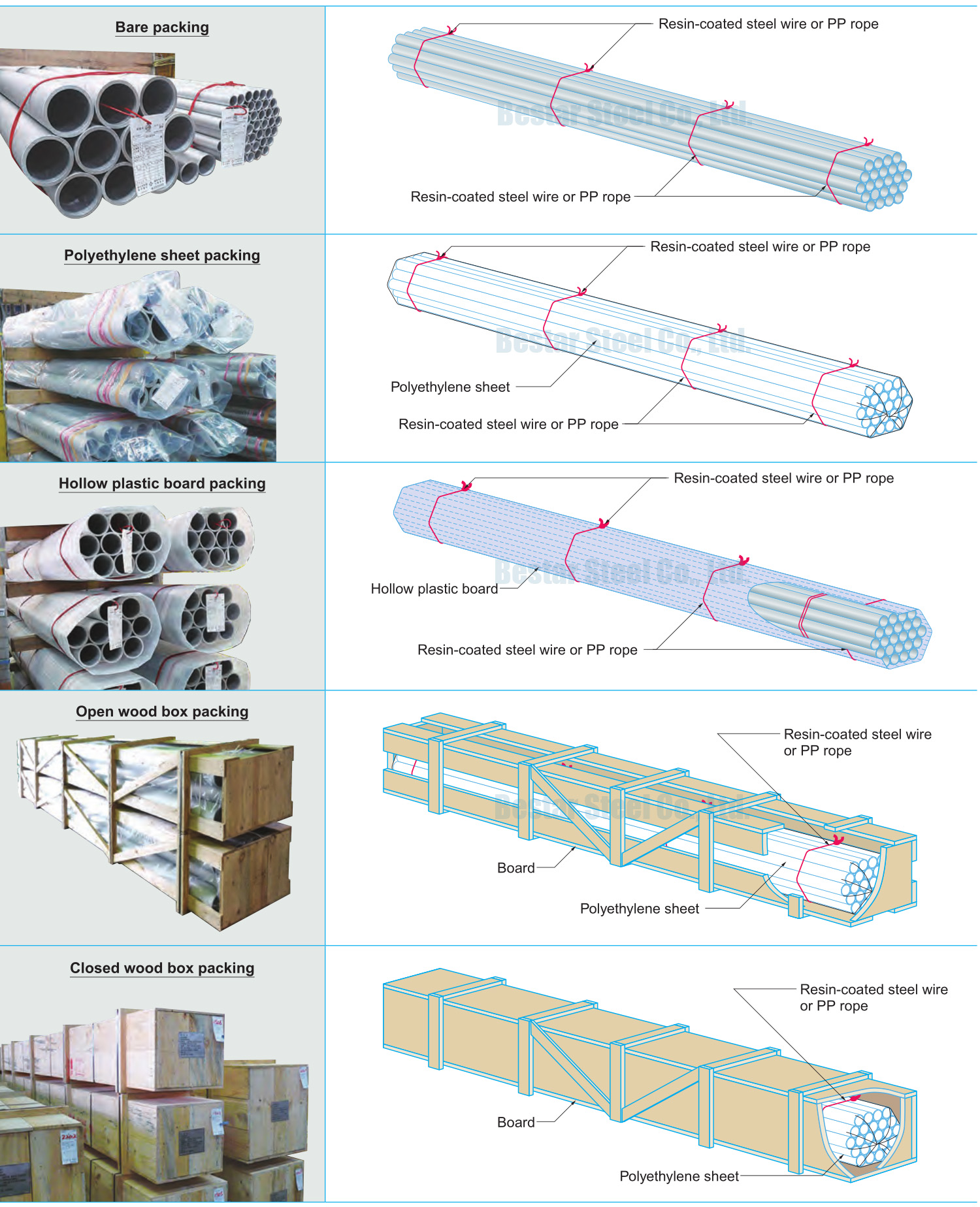

Package : Steel bundle ,Protector on both end .hexagonal bundles of max. 2000kgs with several steel strips , two tags on each bundle , wrapped in waterproof paper , PVC sleeve and sackcloth with several steel strips .

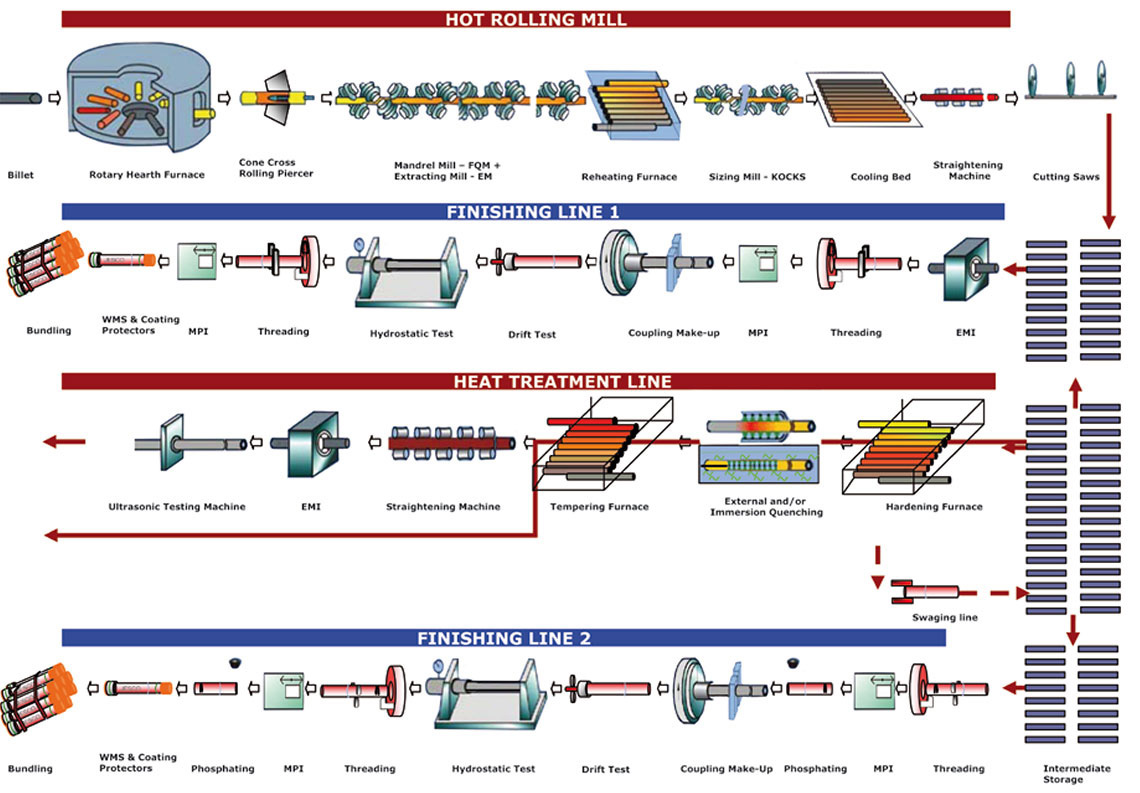

Heat treatment : Normalized , Quencher+Temper

Test : Chemical Component Analysis , Mechanical Properties (Ultimate tensile strenth ,Yield strenth ,Elongation )

Technical Properties ( Flattening test , flaring test , bending test , hardness test , blow test , impact test etc )

Exterior size inspection , Nondestructive test ( Ultrasonic flaw detector , eddy curent flaw detector ) Hydrostatic test .

Mill Test Certificate : EN10204/3.1B and EN10204/3.2 Certificat .

Third Party Inspection : SGS , BV ,LLoyds etc

The most common API tubing specifications are listed here. Others steel grades, nominal weights, and connections are available on request.

|

Label |

OD (mm) |

WT (mm) |

Type of End-finish |

|||||||||

|

|

NU T&C |

EU T&C |

IJ |

H40 |

J55 |

L80 |

N80 |

C90 |

T95 |

P110 |

||

|

1.9 |

2.75 |

2.9 |

2.76 |

48.26 |

3.68 |

PNUI |

PNUI |

PNUI |

PNUI |

PNUI |

PNUI |

- |

|

1.9 |

3.65 |

3.73 |

- |

48.26 |

5.08 |

PU |

PU |

PU |

PU |

PU |

PU |

PU |

|

1.9 |

4.42 |

- |

- |

48.26 |

6.35 |

- |

- |

P |

- |

P |

P |

- |

|

2 3/8 |

4 |

- |

- |

60.32 |

4.24 |

PU |

PN |

PN |

PN |

PN |

PN |

- |

|

2 3/8 |

4.6 |

4.7 |

- |

60.32 |

4.83 |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

|

2 3/8 |

5.8 |

5.95 |

- |

60.32 |

6.45 |

- |

- |

PNU |

PNU |

PNU |

PNU |

PNU |

|

2 3/8 |

6.6 |

- |

- |

60.32 |

7.49 |

- |

- |

P |

- |

P |

P |

- |

|

2 3/8 |

7.35 |

7.45 |

- |

60.32 |

8.53 |

- |

- |

PU |

- |

PU |

PU |

- |

|

2 7/8 |

6.4 |

6.5 |

- |

73.02 |

5.51 |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

|

2 7/8 |

7.8 |

7.9 |

- |

73.02 |

7.01 |

- |

- |

PNU |

PNU |

PNU |

PNU |

PNU |

|

2 7/8 |

8.6 |

8.7 |

- |

73.02 |

7.82 |

- |

- |

PNU |

PNU |

PNU |

PNU |

PNU |

|

2 7/8 |

9.35 |

9.45 |

- |

73.02 |

8.64 |

- |

- |

PU |

- |

PU |

PU |

- |

|

2 7/8 |

10.5 |

- |

- |

73.02 |

9.96 |

- |

- |

P |

- |

P |

P |

- |

|

3 1/2 |

7.7 |

- |

- |

88.9 |

5.49 |

PN |

PN |

PN |

PN |

PN |

PN |

- |

|

3 1/2 |

9.2 |

9.3 |

- |

88.9 |

6.45 |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

|

3 1/2 |

10.2 |

- |

- |

88.9 |

7.34 |

PN |

PN |

PN |

PN |

PN |

PN |

- |

|

3 1/2 |

12.7 |

12.95 |

- |

88.9 |

9.52 |

- |

- |

PNU |

PNU |

PNU |

PNU |

PNU |

|

3 1/2 |

14.3 |

- |

- |

88.9 |

10.92 |

- |

- |

P |

- |

P |

P |

- |

|

3 1/2 |

15.5 |

- |

- |

88.9 |

12.09 |

- |

- |

P |

- |

P |

P |

- |

|

4 |

9.5 |

- |

- |

101.6 |

5.74 |

PN |

PN |

PN |

PN |

PN |

PN |

- |

|

4 |

10.7 |

11 |

- |

101.6 |

6.65 |

PU |

PU |

PU |

PU |

PU |

PU |

- |

|

4 |

13.2 |

- |

- |

101.6 |

8.38 |

- |

- |

P |

- |

P |

P |

- |

|

4 |

16.1 |

- |

- |

101.6 |

10.54 |

- |

- |

P |

- |

P |

P |

- |

|

4 1/2 |

12.6 |

12.75 |

- |

114.3 |

6.88 |

PNU |

PNU |

PNU |

PNU |

PNU |

PNU |

- |

|

4 1/2 |

15.2 |

- |

- |

114.3 |

8.56 |

- |

- |

P |

- |

P |

P |

- |

Mechanical Properties:

|

Standard |

Steel Grade |

Tensile Strength(MPa) |

Yield Strength(MPa) |

Elongation(%) |

Hardness |

|

API SPEC 5CT |

J55 |

≥517 |

379~552 |

0.5% |

|

|

K55 |

≥655 |

379~552 |

0.5% |

|

|

|

N80 |

≥689 |

552~758 |

0.5% |

|

|

|

L80(13Cr) |

≥655 |

552~655 |

0.5% |

≤241HB |

|

|

P110 |

≥862 |

758~965 |

0.6% |

|

Chemical Compositions(%):

|

Standard |

Steel Grade |

Chemical Compositions(%) |

||||||||||

|

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

Mo |

V |

Als |

||

|

API SPEC 5CT |

J55 |

0.34~0.39 |

0.20~0.35 |

1.25~1.50 |

≤0.020 |

≤0.015 |

≤0.15 |

≤0.20 |

≤0.20 |

/ |

/ |

≤0.020 |

|

K55 |

0.34~0.39 |

0.20~0.35 |

1.25~1.50 |

≤0.020 |

≤0.015 |

≤0.15 |

≤0.20 |

≤0.20 |

/ |

/ |

≤0.020 |

|

|

N80 |

0.34~0.38 |

0.20~0.35 |

1.45~1.70 |

≤0.020 |

≤0.015 |

≤0.15 |

/ |

/ |

/ |

0.11~0.16 |

≤0.020 |

|

|

L80(13Cr) |

0.15~0.22 |

≤1.00 |

0.25~1.00 |

≤0.020 |

≤0.010 |

12.0~14.0 |

≤0.20 |

≤0.20 |

/ |

/ |

≤0.020 |

|

|

P110 |

0.26~0.35 |

0.17~0.37 |

0.40~0.70 |

≤0.020 |

≤0.010 |

0.80~1.10 |

≤0.20 |

≤0.20 |

0.15~0.25 |

≤0.08 |

≤0.020 |

|