|

Product |

Line Pipe, API Line Pipe, Seamless Line Pipe, Carbon Steel Line Pipe |

|

Application |

For Transportation in petroleum and natural gas industries |

|

Pipe Standard |

API 5L PSL1/PSL2 Gr.A,Gr.B,X42,X46,X52,X56,X60,X65,X70 |

|

|

API 5L PSL1/PSL2 L210,L245,L290,L320,L360,L390,L415,L450,L485 |

|

Size |

OD: 73-630mm |

|

|

WT: 6-35mm |

|

|

LENGTH: 5.8/6/11.8/12m |

|

Type |

Seamless / ERW / Welded / Fabricated / CDW |

|

Surface Coating |

Epoxy Coating / Colour Paint Coating / 3LPE Coating |

API 5L pipeline is widely utilized in transporting petroleum, gas, water as well as in natural gas industry. API 5L refers to the American Petroleum Institute Prepared and Published all over the world.

Petroleum, crude oil, gas, water or natural gas through API 5L pipeline is transported from the underground to the oil and natural gas industry corporation for further processing production. Oil and gas pipeline includes seamless pipe and welding pipe and has three plain end, threaded end and socket end. Steel grade is mainly Grade B, X42, X46, X52, X56, X65, X70.

Seamless Pipe

Steel Grade: B, X42, X52, X60, X65, X70

Dimension: 1"/2" - 24"

Process:hot rolling, hot expanding

Welding Pipe

Steel Grade: B, X42, X52, X60, X65, X70, X80

Dimension: 2" - 30"

Process: ERW, SSAW, LSAW, HFW, JCOE.

Standard: API 5L / ISO 3183 Hot Rolled

Type: Seamless / ERW / Welded / Fabricated / CDW

Outer Diameter Size: 3/8" NB To 30" NB (Nominal Bore Size)

Wall Thickness: Schedule 20 To Schedule XXS (Heavier On Request) Up to 250 mm Thickness

Length: 5 To 7 Meters, 09 To 13 Meters, Single Random Length, Double Random Length And Customize Size.

Pipe Ends: Plain Ends / Beveled Ends / Coupling

Surface Coating: Epoxy Coating / Colour Paint Coating / 3LPE Coating.

Grades: API 5l Grade B X42, API 5l Grade B X46, API 5l Grade B X52, API 5l Grade B X56, API 5l Grade B X60, API 5l Grade B X65, API 5l Grade B X70

Api 5l Pipe Chemical And Mechanical Properties

The yield strength of an API 5L pipe is specified with the number that follows the X in the material grade designation (in kilopounds per square inch – i.e. KSI). So, for instance, an API 5L X52 pipe has a minimum yield strength of 52 KSI.

The table shows the chemical composition of API 5L steel pipes PSL1 and PSL2 from Grade A to Grade X70, as well as their mechanical properties.

|

API 5L PIPE PSL1 Chemical and Mechanical Properties |

|||||||||

|

API 5L PIPE PSL1 |

Chemical Composition |

Mechanical Property |

|||||||

|

C (Max) |

Mn (Max) |

P (Max) |

S (Max) |

TENSILE ( Min ) |

YIELD ( Min ) |

||||

|

Psi X 1000 |

Mpa |

Psi X 1000 |

Mpa |

||||||

|

Grade A25 |

CL I |

0.21 |

0.60 |

0.030 |

0.030 |

45 |

310 |

25 |

172 |

|

CL II |

0.21 |

0.60 |

0.030 |

0.030 |

|||||

|

Grade A |

0.22 |

0.90 |

0.030 |

0.030 |

48 |

331 |

30 |

207 |

|

|

Grade B |

0.26 |

1.20 |

0.030 |

0.030 |

60 |

414 |

35 |

241 |

|

|

Grade X42 |

0.26 |

1.30 |

0.030 |

0.030 |

60 |

414 |

42 |

290 |

|

|

Grade X46 |

0.26 |

1.40 |

0.030 |

0.030 |

63 |

434 |

46 |

317 |

|

|

Grade X52 |

0.26 |

1.40 |

0.030 |

0.030 |

66 |

455 |

52 |

359 |

|

|

Grade X56 |

0.26 |

1.40 |

0.030 |

0.030 |

71 |

490 |

56 |

386 |

|

|

Grade X60 |

0.26 |

1.40 |

0.030 |

0.030 |

75 |

517 |

60 |

414 |

|

|

Grade X65 |

0.26 |

1.45 |

0.030 |

0.030 |

77 |

531 |

65 |

448 |

|

|

Grade X70 |

0.26 |

1.65 |

0.030 |

0.030 |

82 |

565 |

70 |

483 |

|

API 5L PIPE PSL2 Chemical And Mechanical Properties

|

API 5L PIPE PSL2 Chemical And Mechanical Properties |

||||||||||||

|

API 5L PIPE PSL2 |

Chemical Composition |

Mechanical Property |

||||||||||

|

C |

Mn |

P |

S |

Tensile |

Yield |

C. E. IMPACT ENERGY |

||||||

|

(Max) |

(Max) |

(Max) |

(Max) |

Psi x 1000 |

Mpa |

Psi x 1000 |

Mpa |

PCM |

IIW |

J |

FT/LB |

|

|

Grade B |

0.22 |

1.2 |

0.025 |

0.015 |

60 – 110 |

414 – 758 |

35 – 65 |

241 – 448 |

0.25 |

0.43 |

T/L 27/41 |

T/L 20/30 |

|

Grade X42 |

0.22 |

1.3 |

0.025 |

0.015 |

60 – 110 |

414 – 758 |

42 – 72 |

290 – 496 |

0.25 |

0.43 |

T/L 27/41 |

T/L 20/30 |

|

Grade X46 |

0.22 |

1.4 |

0.025 |

0.015 |

63 – 110 |

434 – 758 |

46 – 76 |

317 – 524 |

0.25 |

0.43 |

T/L 27/41 |

T/L 20/30 |

|

Grade X52 |

0.22 |

1.4 |

0.025 |

0.015 |

66 – 110 |

455 – 758 |

52 – 77 |

359 – 531 |

0.25 |

0.43 |

T/L 27/41 |

T/L 20/30 |

|

Grade X56 |

0.22 |

1.4 |

0.025 |

0.015 |

71 – 110 |

490 – 758 |

56 – 79 |

386 – 544 |

0.25 |

0.43 |

T/L 27/41 |

T/L 20/30 |

|

Grade X60 |

0.22 |

1.4 |

0.025 |

0.015 |

75 – 110 |

517 – 758 |

60 – 82 |

414 – 565 |

0.25 |

0.43 |

T/L 27/41 |

T/L 20/30 |

|

Grade X65 |

0.22 |

1.45 |

0.025 |

0.015 |

77 – 110 |

531 – 758 |

65 – 82 |

448 – 565 |

0.25 |

0.43 |

T/L 27/41 |

T/L 20/30 |

|

Grade X70 |

0.22 |

1.65 |

0.025 |

0.015 |

82 – 110 |

565 – 758 |

70 – 82 |

483 – 565 |

0.25 |

0.43 |

T/L 27/41 |

T/L 20/30 |

|

Grade X80 |

0.22 |

1.9 |

0.025 |

0.015 |

90 – 120 |

621 – 827 |

80 – 102 |

552 – 705 |

0.25 |

0.43 |

T/L 27/41 |

T/L 20/30 |

API 5L Equivalent Grades (ASTM, EN, DIN)

|

Line Pipe Materials: Werkstoff vs EN vs API |

||

|

Werkstoff/DIN |

EN |

API |

|

1.0486 StE 285 |

– |

API 5L Grade X42 |

|

1.0562 StE 355 |

P355N |

API 5L Grade X52 |

|

1.8902 StE 420 |

P420N |

API 5L Grade X60 |

|

1.8905 StE 460 |

P460N |

API 5L Grade X70 |

|

High Yield Steel Pipes |

||

|

1.0457 StE 240.7 |

L245NB |

API 5L Grade B |

|

1.0484 StE 290.7 |

L290NB |

API 5L Grade X42 |

|

1.0582 StE 360.7 |

L360NB |

API 5L Grade X52 |

|

1.8972 StE 415.7 |

L415NB |

API 5L Grade X60 |

API 5L PSL1 VS. API 5L PSL2

API 5L PSL1 and PSL2 are two specification levels that differ in terms of chemical composition and test requirements. The differences between PSL1 and PSL2 are outlined in the two tables below:

|

PSL GRADE |

C, a |

Mn a |

P |

S |

Si |

V |

Nb |

Ti |

Other |

CEIIW |

CEpcm |

|

1 |

0.24 |

1.40 |

0.025 |

0.015 |

0.45 |

0.10 |

0.05 |

0.04 |

b,c |

.043 |

0.025 |

|

2 |

0.28 |

1.40 |

0.03 |

0.03 |

– |

b |

b |

b |

– |

– |

– |

|

Test Requirement |

API 5L PSL1 |

API 5L PSL2 |

|

Charpy test |

None required |

Required for all grades |

|

Seamless NDT test |

Only if purchaser specifies SR4 |

SR4 mandatory |

|

Certification |

Certificates when specified per SR15 |

Certificates (SR 15.1) mandatory |

|

Traceability |

Traceable only until all tests are passed, unless SR15 is specified |

Traceable after completion of tests (SR 15.2) mandatory |

|

Hydrostatic Test |

Required |

Required |

|

Standard |

Type of pipe |

Class |

Grade |

|

API SPEC 5L ISO 3183 |

SMLS |

PLS1 |

L245B, L290 X42, L320 X46 , L360 X52, |

|

|

|

|

L390 X56, L415 X60, L450 X65, L485 X70 |

|

|

|

PLS2 |

L245N BN, L290N X42N, L320N X46N, |

|

|

|

|

L360N X52N, L390N X56N, L415N X60N, |

|

|

|

|

L360Q X52Q, L390Q X56Q, L415Q X60Q , L485Q X70Q |

|

|

|

PLS2 Sour Environment |

L245NS BNS, L290NS X42NS, L320NS X46NS |

|

|

|

|

L360NS X52NS, L390NS X56NS, L415NS X60NS, |

|

|

|

|

L360QS X52QS, L390QS X56QS, L415QS X60QS L485QS X70QS |

|

|

WELD |

PLS1 |

L245B, L290 X42, L320 X46, L360 X52 |

|

|

|

|

L390 X56, L415 X60, L450 X65, L485 X70 |

|

|

|

PLS2 |

L245M BM, L290M X42M, L320M X46M, |

|

|

|

|

L360M X52M, L390M X56M, L415M X60M, |

|

|

|

|

L450M X65M, L485M X70M, L555M X80M, |

|

|

|

PLS2 Sour Environment |

L245MS BMS, L290MS X42MS, L320MS X46MS, |

|

|

|

|

L360MS X52MS, L390MS X56MS, L415MS X60MS, |

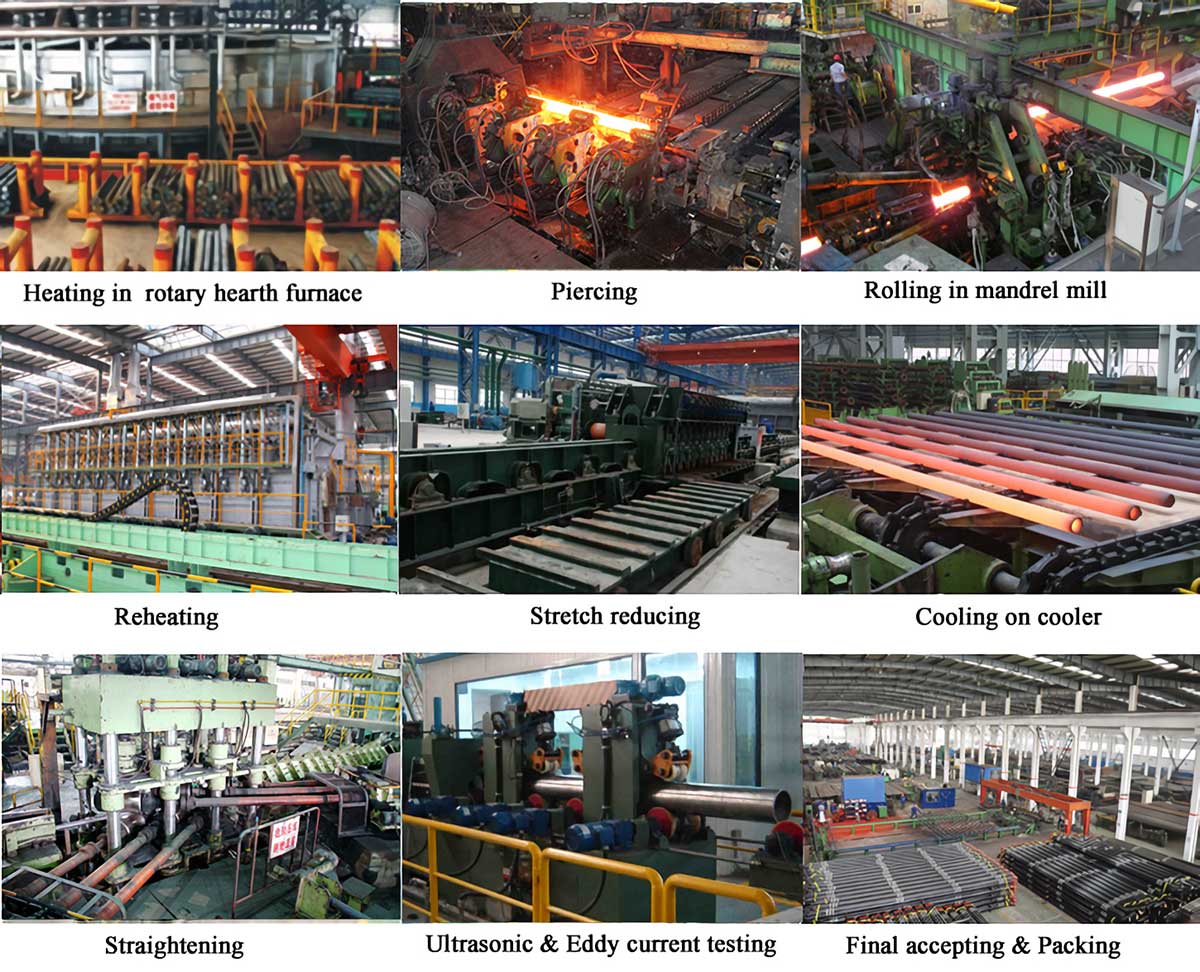

Hot Rolling Seamless Steel Line Pipe Manufacturing / Production processes

Rolled Round Billets – Examination – Cut Off – Heating – Piercing – Elongation – Slight Tension Reducing – Straightening – Corp End Cutting Off – Visual Inspection – NDT – Hydrostatic Test – Ends Procession – Product Inspection – Painting and Marking – Packing – Warehousing

Cold Drawn (Rolled) seamless steel pipe manufacturing process

Mother pipe (Normally for hot rolled pipe) – Inspection – Annealing – Ends Treatment (Hitting and Drilling hole) – Pickling – Grinding – Phosphorization (Annoit) – Cold Drawn (Rolled) – Degreasing and Cleaning – Heat treatment (Solution treatment) – Straightening – Hydrostatic test – Painting and Marking – Warehousing