|

Product: |

Liquid epoxy coating pipe, Epoxy Coated Pipe, Epoxy Coated Carbon Steel Pipe |

|

Application: |

Used for natural gas, petroleum, water & sewage, and pipe systems |

|

Standard: |

AWWA C210 |

|

Size: |

60.3mm-2540mm |

|

End: |

Plain End/Bevelled End, Burr Removed |

|

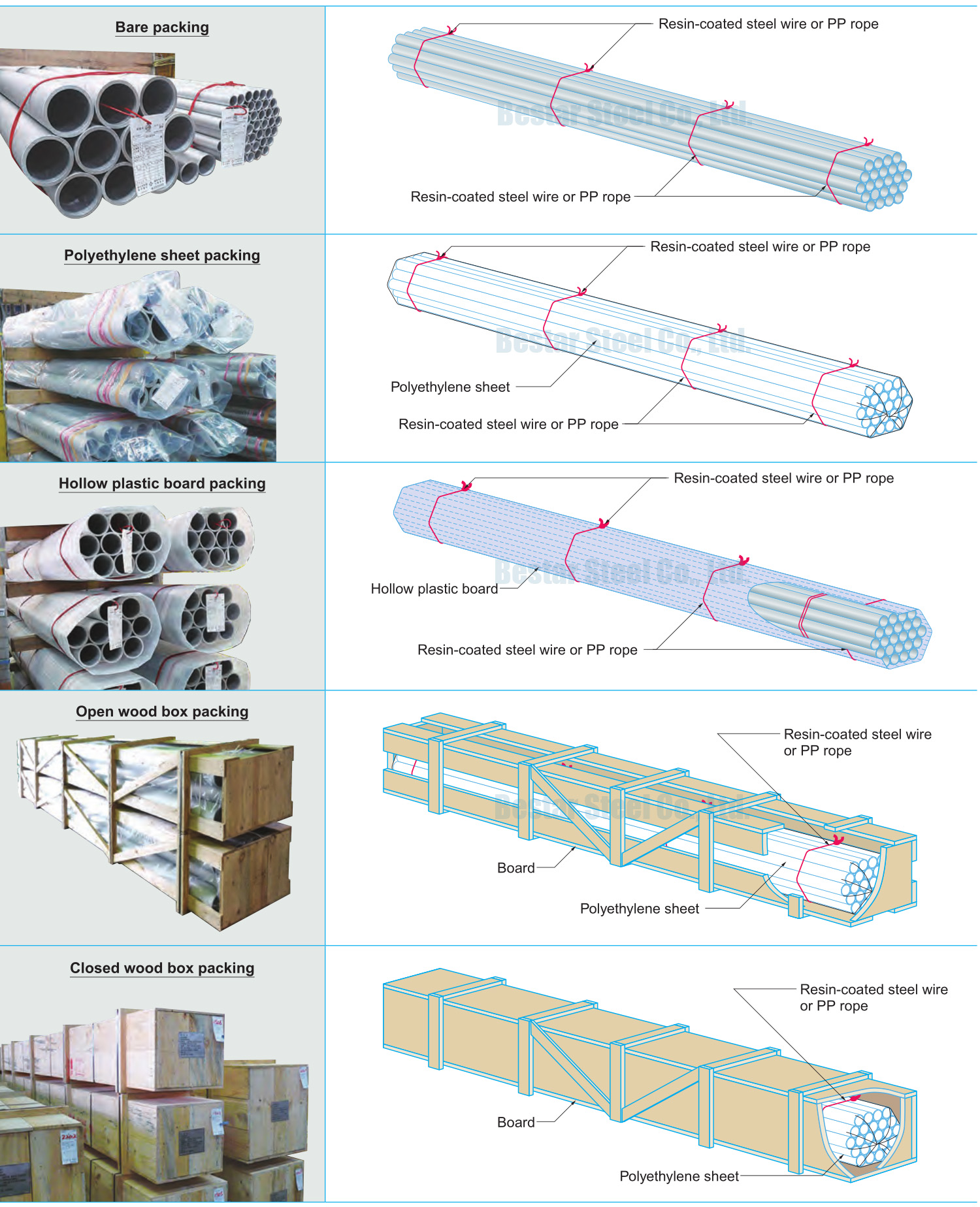

Packing: |

Waterproof Paper wrapped, Steel Strips bundled, two tags on each bundle |

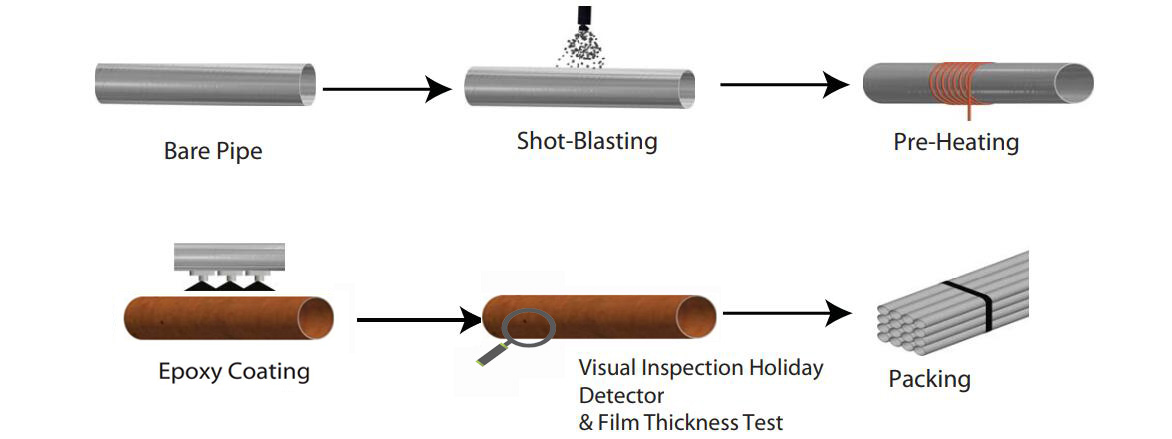

What does Liquid Epoxy Coating mean?

Liquid epoxy coating is a coating system composed of two substances. It is mainly applied on floors and gives off a unique finish compared to traditional coatings because of its distinct chemical composition.

The two elements of liquid epoxy coating are kept separated before application. When combined, these components, which are composed of thermosetting polymers, go through a chemical reaction which builds a closely impassable bond. Once this reaction has occurred, liquid epoxy coating can be very difficult to remove. Removal typically necessitates breaking the liquid epoxy coating bond with the use of a methylene chloride or extreme heat.

Traditionally, liquid epoxy coating has been applied in commercial settings, most particularly warehouse and automotive facilities. This is the case since this type of coating is low maintenance and extremely durable, even to recurrent chemical or gasoline spills, vehicle traffic and other hazards.

Due to its flawless nature, it has become popular both in laboratory and medical settings. It is highly capable of producing a clean-room floor free of the risks for dirt and mold buildup. Liquid epoxy coating is also utilized in other industries like schools and animal facilities because of the convenience in cleaning it presents. Even modern homeowners have started using this coating due to its capacity to endure grease stains and oil.

Other benefits of liquid epoxy coating include:

It acts as a coating and filler at the same time.

It can be easily applied on uneven and rough surfaces quite easily.

It is resistant to various elements such as acid, rust, chemicals, corrosion and heat.

It is waterproof.

It is cost effective compared to other forms of coating.

In applying liquid epoxy coating, the surface should be totally cured, dried and de-greased with the help of a pressure washer. Then, it should be etched using a mixture of muriatic acid and water. The application process should be quick, as it dries fast. Most of all, wearing a ventilator is essential to avoid injuries or illnesses.

Epoxy Lining: AWWA C210 - White, or approved equal for shop and field joint

applied, except as modified herein.

1. Surface Preparation: SSPC-SP-10(64); Near White Blast Clean; 2.0 to 3.0 mils surface profile.

2. Prime Coat: ACRO 4460 NSF Certified Epoxy - Buff; 4.0 to 6.0 mils DFT or approved equal.

3. Intermediate Coat: ACRO 4460 NSF Certified Epoxy - Buff: 4.0 to 6.0 mils DFT or approved equal.

4. Finish Coat: ACRO 4460 NSF Certified Epoxy - White 4.0 to 6.0 mils DFT or approved equal.

5. Minimum allowable dry film system thickness: 12.0 mils.

6. Maximum allowable dry film system thickness: 18.0 mils.

7. Minimum field adhesion: 700 psi.

8. Dry film thicknesses for approved alternate products in accordance with the product manufacturer's recommendations.

9. The lining system may consist of three or more coats of the same approved alternate epoxy lining without the use of a separate primer.

10. Provide materials from the same manufacturer.

AWWA C210 Liquid-Epoxy Coating Systems for the Interior and Exterior of Special Sections, Connections, and Fittings for Steel Water Pipelines

The coatings and linings specified in AWWA C210 consist of two-part chemically cured liquid epoxies, specifically those applications that can fall into any of the following categories:

A combination of an epoxy primer and one or more layers of an epoxy topcoat

Two or more coats of the same epoxy, where the first layer is considered the primer and subsequent layers are considered the topcoat(s)

A single coat of epoxy

This standard applies to both field-applied and shop-applied liquid epoxy used under normal construction conditions in the water supply industry.

How to Comply with AWWA C210?

Epoxy coatings and linings are protective barriers between the steel pipe or fitting substrate and the surrounding environment. The application of epoxy products creates a chemical-resistant, durable, flexible, and long-lasting shield that prevents corrosion, has low maintenance requirements, and extends the service life of the transmission pipe or fitting.

As the purpose of AWWA C210 is to outline the minimum requirements for liquid epoxy coatings and linings used to protect underground or underwater steel water pipes and fittings, water supply professionals can abide by the standard by using AWWA C210-compliant products.

AWWA C210 epoxy coating and lining products designed for steel water pipes and fittings have passed rigorous tests to make sure they are up to par. By manufacturing, purchasing, or using an AWWA C210-compliant liquid epoxy coating or lining system, you ensure that the product meets the standards agreed upon by water supply industry professionals and can rest assured that it will work as intended.