|

Product: |

FBE Coated Pipe, Fusion Bond Epoxy Coated Pipe, FBE Coating Steel Pipe |

|

Application: |

Used for natural gas, petroleum, water & sewage, and pipe systems |

|

Standard: |

DIN30670 |

|

Size: |

DN50-DN2200 |

|

End: |

Plain End/Bevelled End, Burr Removed |

|

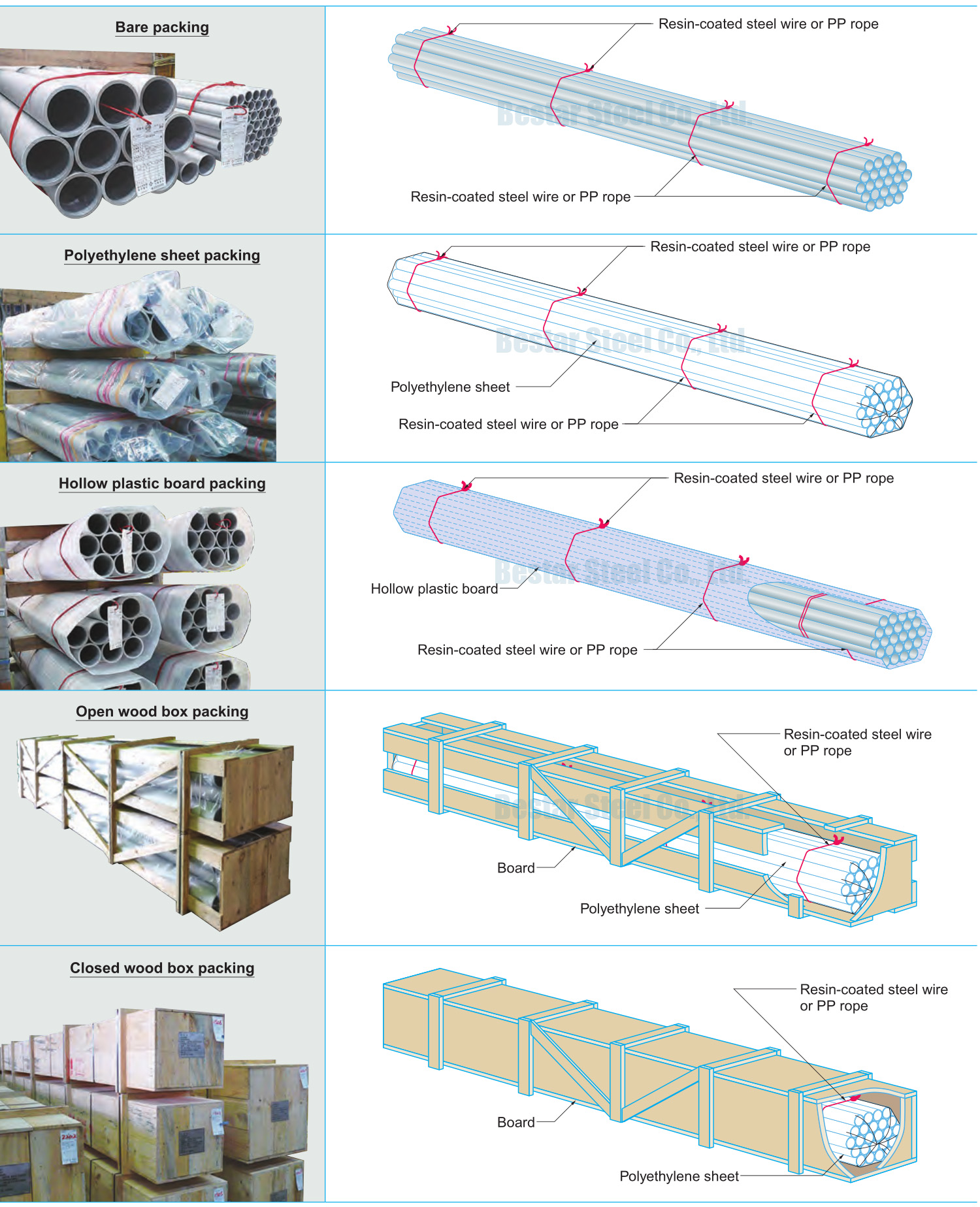

Packing: |

Waterproof Paper wrapped, Steel Strips bundled, two tags on each bundle |

FBE coating steel pipe is fusion bonded epoxy coating steel pipe.It is a kind of external heat resin used for pipes.With a form of dry powder at thickness 400-600 microns on to the heated surface of pipe.Once the FBE coated on the pipe surface,the FBE film provides an extremely hard surface with great adhesion to the surface of pipe.The FBE layer in a even form and have good resistance to the chemical reaction.

Fusion bonded epoxy (FBE) coating are used to prevent corrosion and harmful chemicals of steel pipes.This is a thin coating made of epoxy-resin powder material in a thin film and applied to pipes by a special coating device for electrostatic spraying.These FBE coated pipes can be used in temperatures up to 85oC in dry conditions.

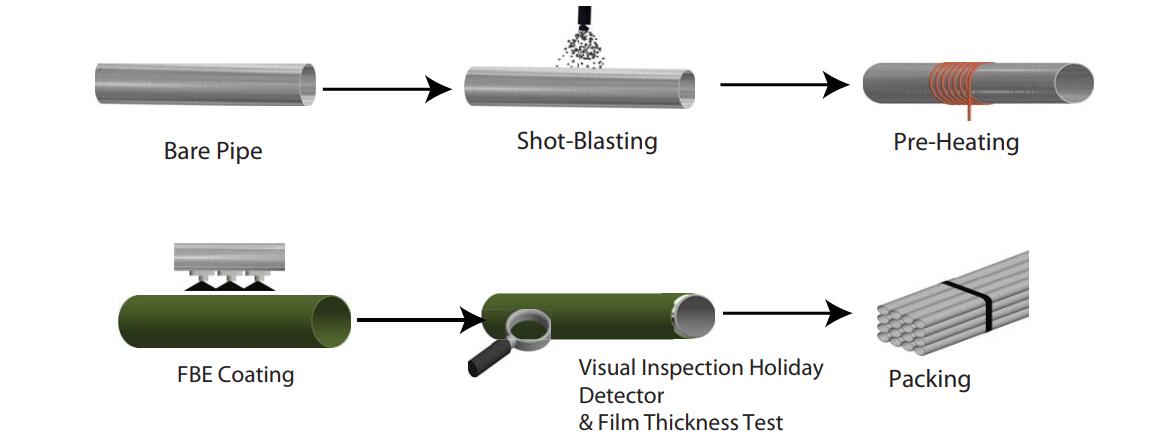

The steel pipes are treated by shot blasting and intermediate frequency preheating before painting, and then the epoxy powder coating is sprayed on the surface of the heated pipe products by electrostatic spraying method, which is fused and bonded on the surface of the steel pipe and solidified to form a coating. FBE coating is usually one – step film – forming structure.

Features of fusion bonded epoxy(FBE) coating steel pipes:

FBE coating is corrosion resistant and chemical resistant

FBE coating has strong adhesion to steel, film integrity, soil stress and wear resistance.

FBE coating increases the life span of steel pipes.

The FBE coating can be used for external corrosion protection of buried or underwater steel piping installations with operating temperatures of -30~100 °c.

On the other hand,the defect of the FBE steel pipe is it have poor resistance to mechanical damage and heat and humidity.

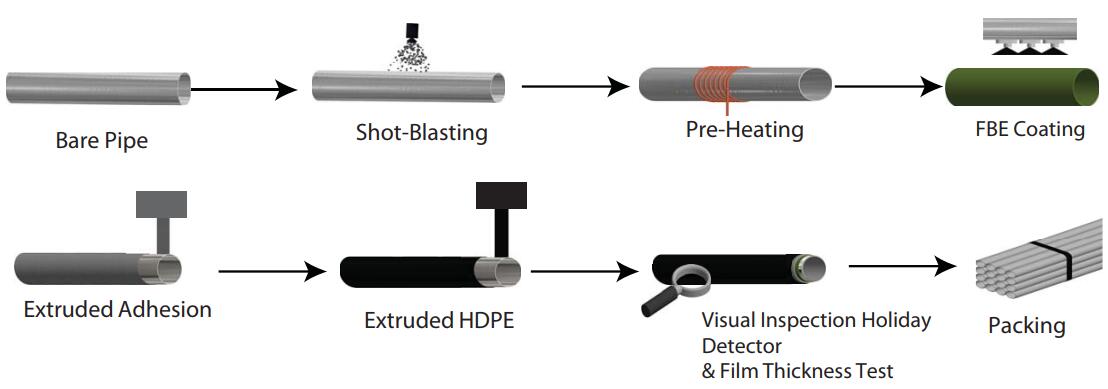

A three-layer extruded polyethylene coating (3LPE) is composed of extruded, three-layer, anti-corrosive steel pipe coatings.

3 LPE COATING ACC. TO DIN 30670

Layer 1: This is a layer is of fusion bonded epoxy used for good corrosion protection.

Layer 2: Second layer is the copolymer adhesive and has good chemical bonding with both layesr of fusion bonded epoxy (FBE) and the top layer polyethylene.

Layer 3: This top layer is consists of polyethylene to bond well with each other

Third layer of polyethylene coated pipes are the preferred choice for transmission of oil and gas around the world. It can withstand varying temperatures and environments ranging from desert drylands to deep underwater regions. 3LPE coated steel pipes are used for transportation of oil and gas, drinking water and other fluids. 3LPE coated pipes can be used in the high temperatures as high as 60 to 80°c.

What is DIN 30670 Standard?

The present standard specifies requirements for coatings that are applied to longitudinally or spirally welded or seamless steel pipes and fittings used for the construction of pipelines for conveying liquids or gases.

Applying this standard ensures that the PE coating provides sufficient protection against the mechanical, thermal and chemical loads occurring during operation, transport, storage and installation.

THICKNESS OF 3LPE COATING ON STEEL PIPES

minimum 125 µm Epoxy layer thickness

minimum 150 µm copolymer layer thickness

minimum thickness of 1.8 mm to 4.7 mm polyethylene or polypropylene layer

Minimum total layer thickness range

|

M kg/m |

Layer thickness in mm |

||||||||

|

Class A1 |

Class A2 |

Class A3 |

Class B1 |

Class B2 |

Class B3 |

Class C1 |

Class C2 |

Class C3 |

|

|

M ≤ 15 |

1,8 |

2,1 |

2,6 |

1,3 |

1,8 |

2,3 |

1,3 |

1,7 |

2,1 |

|

15 < M ≤ 50 |

2,0 |

2,4 |

3,0 |

1,5 |

2,1 |

2,7 |

1,5 |

1,9 |

2,4 |

|

50 < M ≤ 130 |

2,4 |

2,8 |

3,5 |

1,8 |

2,5 |

3,1 |

1,8 |

2,3 |

2,8 |

|

130 < M ≤ 300 |

2,6 |

3,2 |

3,9 |

2,2 |

2,8 |

3,5 |

2,2 |

2,5 |

3,2 |

|

300 < M |

3,2 |

3,8 |

4,7 |

2,5 |

3,3 |

4,2 |

2,5 |

3,0 |

3,8 |

|

Please note: The total required thickness may be reduced for SAW pipes by a maximum of 10% on joint seam. |

|||||||||

Minimum thickness of finished coating

|

Pipe Sizes (Specified OD) |

Minimum Coating Thickness Chart (mm) |

|

≤ 10 3 /4” (273.1 mm) |

2.5 |

|

> 12 3 /4” ( 323.9 mm) to ≤ 18” (457 mm) |

2.8 |

|

> 20" (508.0 mm) to ≤ 30" (762 mm) |

3.0 |

|

> 32" (813.0 mm) |

3.3 |

THICKNESS OF FBE COATING ON STEEL PIPES

|

DN (mm) |

Epoxy Powder (μm) |

Adhesive Layer (μm) |

Min. Thickness on The Coating (mm) |

|

|

Common Level (G) |

Strengthen Level (S) |

|||

|

DN ≤ 100 |

≥120 |

≥170 |

1.8 |

2.5 |

|

100 < DN ≤250 |

2.0 |

2.7 |

||

|

250 < DN < 500 |

2.2 |

2.9 |

||

|

500 ≤DN < 800 |

2.5 |

3.2 |

||

|

DN ≥ 800 |

3.0 |

3.7 |

||

DIN 30670-2012 Polyethylene Coatings on Steel Pipes and Fittings

ISO 21809-1:2011 Petroleum and natural gas industries -- External coatings for buried or submerged pipelines used in pipeline transportation systems -- Part 1: Polyolefin coatings (3-layer PE and 3-layer PP)

CAN CSA Z245.21 External Polyethylene Coating for Pipe

NFA 49-710 External Three-Layer Polyethylene Based Coating, Application by Extrusion

SHELL DEP 31.40.30.31-CSPC External Polyethylene and Polypropylene Coating for Line Pipe

Process Flowchart of 3LPE Coating

Process Flowchart of FBE Coating