|

Product: |

3LPE Coated Pipe, 3LPE Coated Seamless Steel Pipes, 3 layers for pipeline coating |

|

Application: |

Used for natural gas, petroleum, water & sewage, and pipe systems |

|

Standard: |

DIN30670 |

|

Size: |

DN50-DN2200 |

|

End: |

Plain End/Bevelled End, Burr Removed |

|

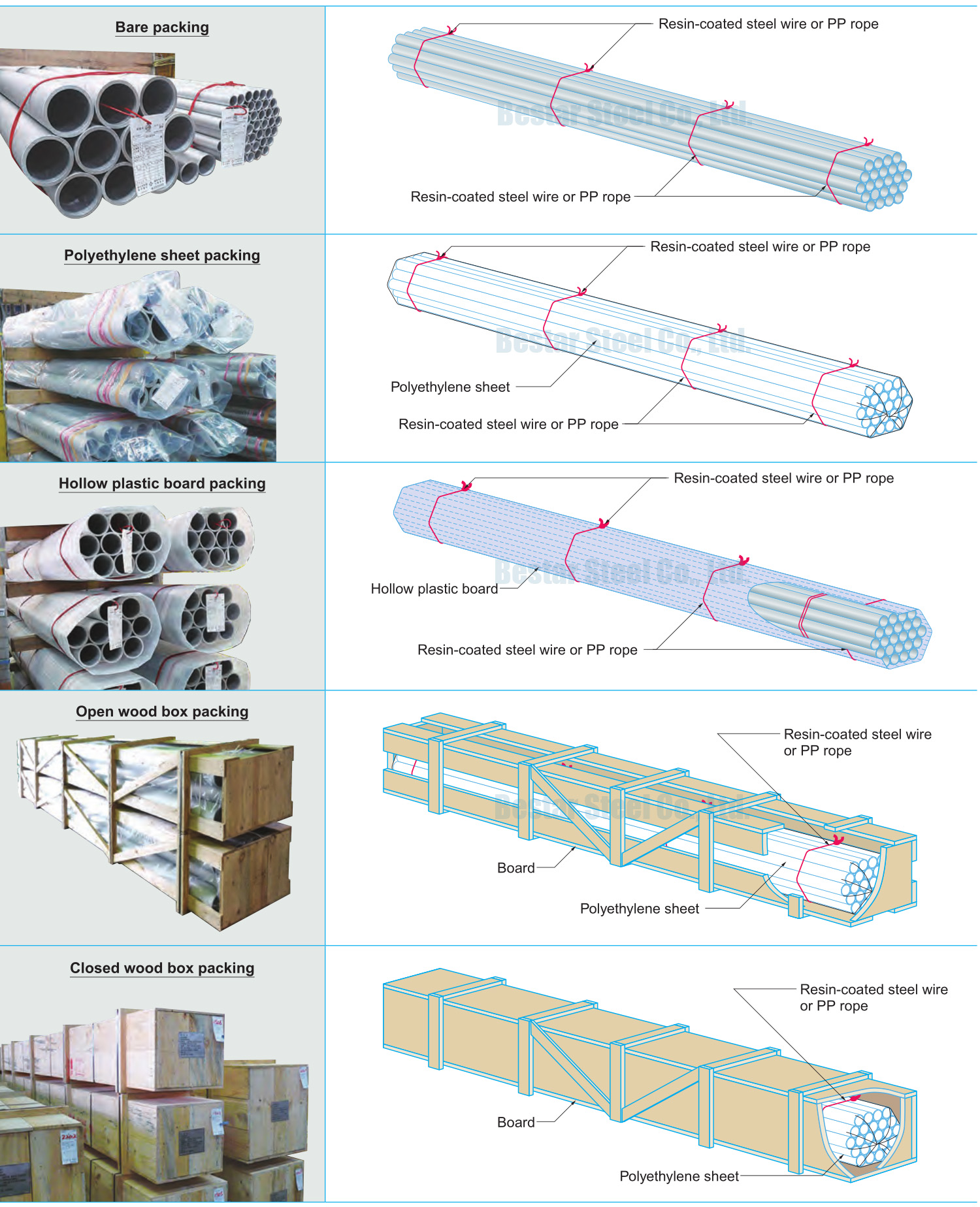

Packing: |

Waterproof Paper wrapped, Steel Strips bundled, two tags on each bundle |

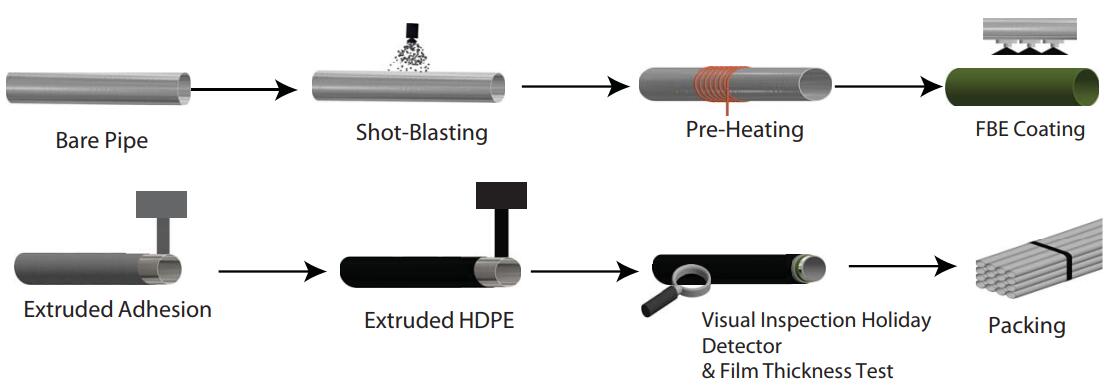

What is 3LPE coated pipe?

3LPE Coated Pipes consist of 3 layers for pipeline coating.

Layer 1 consists of Fusion Bonded Epoxy. This later protects against corrosion and is fusion bonded with the blasted steel surface.

Layer 2 is a copolymer adhesive that has excellent chemical bonding to the inner layer and the top layer of polyethylene.

Layer 3 is the layer of polyethylene used for protection against any physical damage to the pipes.

The 3 layer polyethylene coated pipes are the preferred choice for the transmission of oil and gas around the world. It can withstand varying temperatures and environments ranging from desert dry lands to deep underwater regions. 3LPE-coated steel pipes are used for the transportation of drinking water, oil and gas, and other fluids. The 3LPE-coated pipes can be used in high temperatures as high as 60℃ to 80℃.

Features of 3LPE coated pipes:

1. Excellent chemical and corrosion resistance preventing steel pipes from any damage.

2. Resistance to cathodic disbondment

3. The external layer of polyethylene prevents any physical damage to either the pipes or the fusion-bonded epoxy during handling

4. The 3LPE coated pipes have high-performance characteristics and an extended life cycle

THICKNESS OF 3LPE COATING ON STEEL PIPES

minimum 125 µm Epoxy layer thickness

minimum 150 µm copolymer layer thickness

minimum thickness of 1.8 mm to 4.7 mm polyethylene or polypropylene layer

Minimum total layer thickness range

|

M kg/m |

Layer thickness in mm |

||||||||

|

Class A1 |

Class A2 |

Class A3 |

Class B1 |

Class B2 |

Class B3 |

Class C1 |

Class C2 |

Class C3 |

|

|

M ≤ 15 |

1,8 |

2,1 |

2,6 |

1,3 |

1,8 |

2,3 |

1,3 |

1,7 |

2,1 |

|

15 < M ≤ 50 |

2,0 |

2,4 |

3,0 |

1,5 |

2,1 |

2,7 |

1,5 |

1,9 |

2,4 |

|

50 < M ≤ 130 |

2,4 |

2,8 |

3,5 |

1,8 |

2,5 |

3,1 |

1,8 |

2,3 |

2,8 |

|

130 < M ≤ 300 |

2,6 |

3,2 |

3,9 |

2,2 |

2,8 |

3,5 |

2,2 |

2,5 |

3,2 |

|

300 < M |

3,2 |

3,8 |

4,7 |

2,5 |

3,3 |

4,2 |

2,5 |

3,0 |

3,8 |

|

Please note: The total required thickness may be reduced for SAW pipes by a maximum of 10% on joint seam. |

|||||||||

Minimum thickness of finished coating

|

Pipe Sizes (Specified OD) |

Minimum Coating Thickness Chart (mm) |

|

≤ 10 3 /4” (273.1 mm) |

2.5 |

|

> 12 3 /4” ( 323.9 mm) to ≤ 18” (457 mm) |

2.8 |

|

> 20" (508.0 mm) to ≤ 30" (762 mm) |

3.0 |

|

> 32" (813.0 mm) |

3.3 |

DIN 30670

CSA Z245.21

AS 4321

IS 3581

3 LPE coating acc. To DIN 30670

Layer 1: This is a layer is of fusion bonded epoxy used for good corrosion protection.

Layer 2: Secon layer is the copolymer adhesive and has good chemical bonding with both layesr of fusion bonded epoxy (FBE) and the top layer polyethylene.

Layer 3: This top layer is consists of polyethylene to bond well with each other