2024-08-14

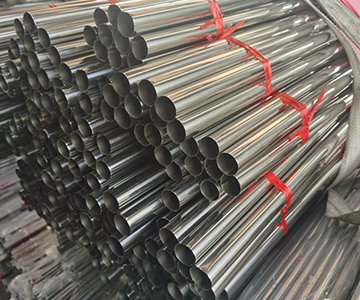

Steel pipe, as an indispensable material in construction, machinery manufacturing, and other fields, carries important functions and responsibilities. 30Mn2 seamless steel pipe is one of them. Its quality, characteristics, and application fields are worthy of our in-depth understanding and discussio