2025-03-06

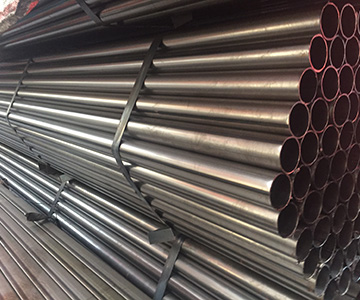

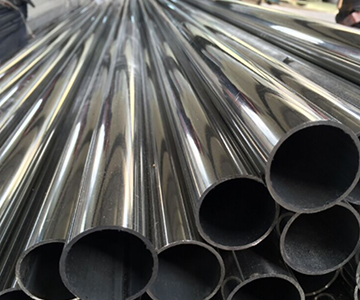

Seamless steel pipe is a commonly used pipe material, widely used in oil, natural gas, chemical industry, electricity, heating, gas supply, machinery, construction, and other fields. Seamless steel pipes can be divided into various specifications according to wall thickness and diameter, and seamles