2023-09-20

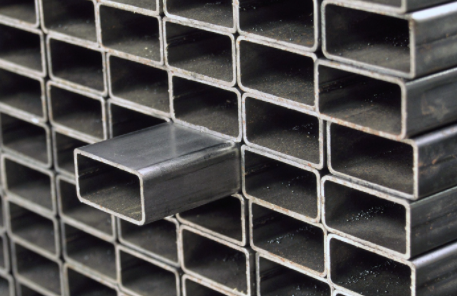

Seamless pipes have emerged as a vital component in several key industries, offering unmatched reliability, strength, and versatility. At Bestar Steel, we take pride in manufacturing high-quality seamless pipes tailored to the specific demands of industries such as petroleum, aerospace, chemical, power generation, boilers, and the military. In this article, we will delve into the diverse applications and advantages of seamless pipes in these pivotal sectors.