2023-08-01

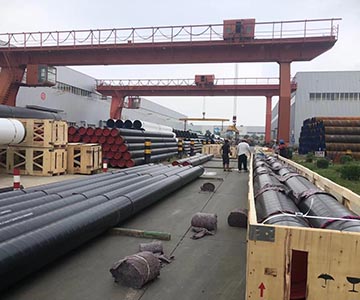

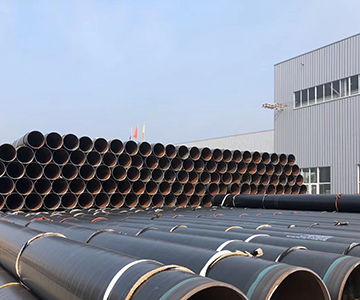

1) the single-layer epoxy powder anti-corrosion steel pipe coating has good chemical resistance and solvent resistance, can resist the chemical corrosion of h2s, co2, o2, acid, alkali, salt, organic matter, and other substances in the transmission medium, and can long-term contac