2023-01-27

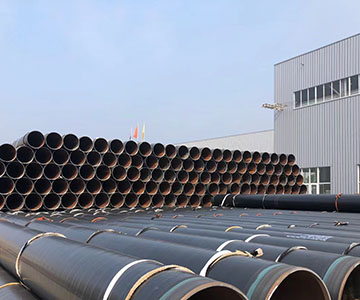

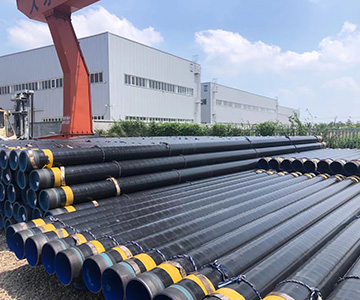

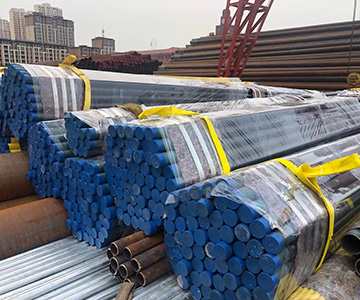

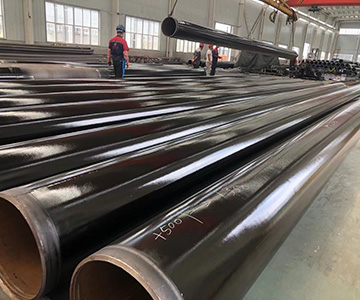

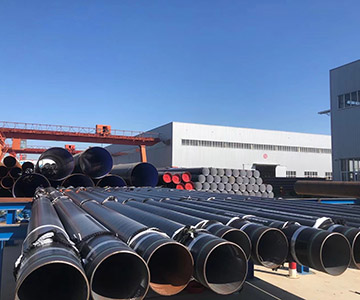

1. spraying process of 3pe anti-corrosion steel pipeat present, most 3pe anti-corrosion steel pipe manufacturers in my country adopt the production process of "epoxy powder spraying, adhesive, and polyethylene lateral extrusion, winding roll pressing", because the method of powder and elec