|

Product: |

ERW (Electric Resistance Welded ) Steel Pipe, HFW Pipe, ERW Black Pipe |

|

Application: |

Used for Oil/Gas/Water transmission,Machinery Manufacturing |

|

Size: |

OD: 21.3-660mm |

|

|

WT: 1.0-20mm |

|

|

LENGTH: 5.8/6/11.8/12m |

|

Ends: |

Square Ends/Plain Ends (straight cut, saw cut, torch cut), Beveled/Threaded Ends |

|

Pipe Standard: |

API 5L PSL1/PSL2 Gr.A,Gr.B,X42,X46,X52,X56,X60,X65,X70 |

|

|

ASTM A53/A252/A500/A178/A135 |

|

|

EN10210/EN10219/EN10217/EN10208/EN10297 |

|

|

JIS G3441/G3444/G3445/G3452/G3454/G3456 |

|

|

BS1387/AS1163 |

|

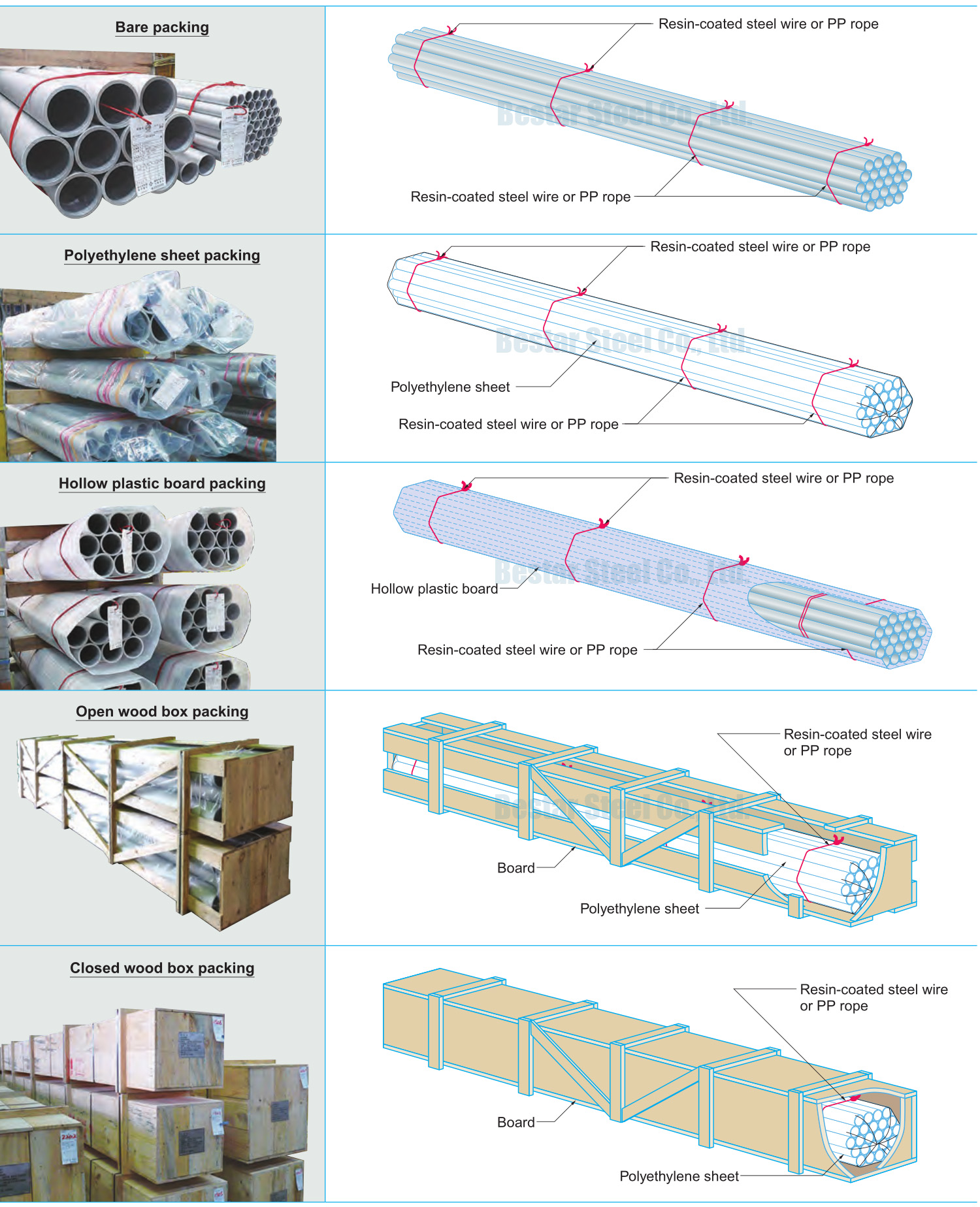

Packing: |

Bundled/In Bulk, Plastic Caps Plugged, Waterproof Paper Wrapped |

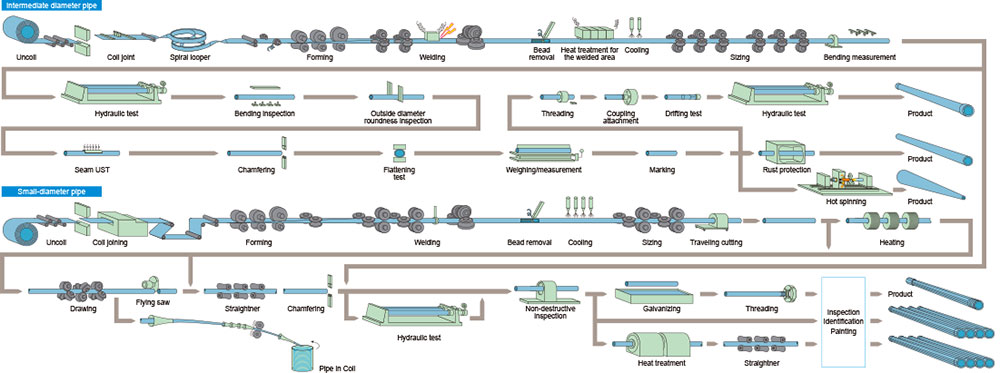

The High-Frequency Longitudinal Seam Welded Steel pipe is also called ERW steel pipe, it's manufactured by cold-forming a sheet of steel into a cylindrical shape. Current is then passed between the two edges of the steel to heat the steel to a point at which the edges are forced together to form a bond without the use of welding filler material.

MAIN CHARACTERISTICS OF ERW STEEL PIPES:

High-security welding seam: as a result of special welding method of melting of the parent metal together without filler metal, the welding property is better and the welding seam is much smaller than spiral welded pipes.

Cost effective and short production period

A wide range of thickness/diameter ratio, covering hundreds of specification

In –line inspection and testing

APPLICATION OF ERW PIPES:

Casing and tubing: lined inside drilling well. Seamless pipes use to be the only choice for lining pipes inside drilling well, but as the worldwide acknowledgement of ERW pipe’s high-quality weld seam and the cost-effective, more and more projects have been choosing ERW instead of seamless pipe.

Constructional structural pipes(round, square and rectangular): round, square and rectangular ERW structural pipes are widely used in frameworks of shopping centres, theatres, airports, bridges, workshops etc.

Low-pressure flow transmitting: ERW pips are also used in water supply; cooling water supply for plants and equipment; low pressure thermal distributing; coal slurry transportation and more.

Pipes for raw materials in the manufacturing industry: automobile vent-pipe; low and intermediate pressure boiler pipes; bulk matters transportation pipes.

Other application: piling pipes, furniture fabricating and more.

|

Outside Diameter |

Wall Thickness |

||

|

DN |

Inch |

mm |

mm |

|

|

1/2" |

20~21.3 |

0.95~2.77 |

|

20 |

3/4" |

25~26.9 |

1.1~2.87 |

|

25 |

1" |

32~33.7 |

1.1~4.0 |

|

32 |

11/4" |

40~42.4 |

1.1~4.0 |

|

40 |

11/2" |

47~48.3 |

1.5~7.0 |

|

50 |

2" |

58~60.3 |

1.8~7.0 |

|

65 |

2 1/2" |

73~76.1 |

2.0~7.0 |

|

80 |

3" |

87~88.9 |

2.2~8.0 |

|

90 |

3 1/2" |

101.6~102.1 |

2.2~9.0 |

|

100 |

4" |

113~114.3 |

2.2~9.0 |

|

125 |

5" |

140~141.3 |

2.5~10.0 |

|

150 |

6" |

165~168.3 |

2.5~10.0 |

|

200 |

8" |

216~219.1 |

2.75~12.0 |

|

250 |

10" |

272.8~273.2 |

5.0~13.75 |

|

300 |

12" |

323.8~325 |

5.5~13.75 |

|

350 |

14" |

355.6~356 |

5.5~13.75 |

|

400 |

16" |

406~406.4 |

5.75~13.75 |

|

450 |

18" |

457~457.2 |

5.75~17.75 |

|

500 |

20" |

507.9~508.1 |

5.75~17.75 |

|

600 |

24" |

609~610 |

5.75~17.75 |

|

Standard code content items |

SY/T5037 -2000 |

T9711 -1997 (A class pipe) |

API 5L(43 version) |

||

|

Applications |

Gas, water, kerosene, air, heating, steam and other general fluid pipes with steel pipes |

Oil and gas industry transmission pipe |

Oil and gas industry transmission pipe |

||

|

Steel |

Q195、Q215、Q235 |

L175 -L483 |

A、B、X42 ~ X70 |

||

|

Size |

body OD |

D<508 ±0.75%DD≥508 ±1.00%D |

D<508 ±0.75%DD≥508 ±1.00%D |

D<508 ±0.75%D508≤D≤914 -0.25%D ~ +0.75%DD>914 -0.32%D ~ +6.35%D |

|

|

|

end OD |

D<508 ±0.75%D or ±2.5 be minimumD≥508 ±0.50%D or ±45 be minimum |

D≤273.1 -0.40 ~ +1.59D>323.9 -0.79 ~ +2.38 |

D≤273.1 -0.40 ~ +1.59D>323.9 -0.79 ~ +2.38 |

|

|

Tolerance |

W.T. |

<508 |

±12.5%t |

-12.5%t ~ +12.5%t |

-12.5%t ~ +12.5%t |

|

|

|

≥508 |

±10.0%t |

L175 ~ L245 -10.0%t ~ +17.15%tL290 ~ L555 -8.0%t ~ +19.5%t |

Not beyond B class -12.5%t ~ +17.5%tNot lower than X42 -8.0%t ~ +19.5%t |

|

Oval tube |

Inner tube end range 100 ±1%D |

D>508 steel in the range from 101.6 max OD of the pipe end can not be larger than the DN of 1%D; smallest OD than the DN shall be 1% D |

D>508 steel in the range from 101.6 max OD of the pipe end can not be larger than the DN of 1%D; smallest OD than the DN shall be 1% D |

||

|

Curvature degree(straightness) |

Not exceed 0.2% of the pipe length |

Not exceed 0.2% of the pipe length |

Not exceed 0.2% of the pipe length |

||

|

Pipe end beveling |

Bevel degree 30° -35° blunt edge1.6±0.8 |

Bevel degree 30° -35° blunt edge 1.59±0.79 |

Bevel degree 30° -35° blunt edge 1.59±0.79 |

||

|

Tilt |

1.6≤D<813 |

<1.59 |

<1.59 |

||

|

Misalignment |

t≤12.7 |

0.35t and not more than 3.0 |

<1.59 |

<1.59 |

|

|

|

t>12.7 |

0.25t |

0.1251 and 3.18 take the minimum value |

0.1251 and 3.18 take the minimum value |

|

|

Weld reinforcement |

t≤13…<3.2t>13 <4.8 |

t≤12.7…<3.18t>12.7 <4.76 |

t≤12.7…<3.18t>12.7 <4.76 |

||

|

Chemical analysis |

Take one sample from each batch |

Take two samples from each batch |

Take two samples from each batch |

||

|

Tensile test |

Take one welded joint sample from each batch |

Base matel: take one sample from each smelting batchSpiral weld:take one sample from each smelting batch butt weld: not more than 50 to take one sample |

Base matel: take one sample from each smelting batchSpiral weld:take one sample from each smelting batch butt weld: not more than 50 to take one sample |

||

|

Guided bend test |

No |

Each batch take a positive test sample and an anti-bend bend sample, butt weld no more than 50 to take a positive bend and an anti-bend sample. |

Each batch take a positive test sample and an anti-bend bend sample, butt weld no more than 50 to take a positive bend and an anti-bend sample. |

||

|

Fracture toughness testing |

No |

When the contract requirements,smelting complex batch takes three samples; D≥508, the drop hammer impact each smelting batch take two. |

When the contract requirements,smelting complex batch takes three samples; D≥508, the drop hammer impact each smelting batch take two. |

||

|

ASTM A53 |

Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless |

|

API 5L |

Specification for Line Pipe(Two levels PSL 1 and PSL 2 of seamless and welded steel pipes for use in pipeline transportation systems in the petroleum and natural gas industries.) |

|

A252 |

Standard Specification for Welded and Seamless Steel Pipe Piles |

|

A500 |

Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes |

|

A135 |

Standard Specification for Electric-Resistance-Welded Steel Pipe |

|

A178 |

Standard Specification for Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater Tubes |